Sep. 17, 2025

Nowdays, many abroad foundry clients find us and confirm with us: they urgently need to change their stainless steel filter mesh to be our fiberglass filter mesh.

There are three kind of such fiberglass filter mesh:

1. High Silica Fiberglass Filter Mesh For Steel

2. High Silica Fiberglass Filter Mesh For Iron

3. Fiberglass Filter Mesh For Aluminum

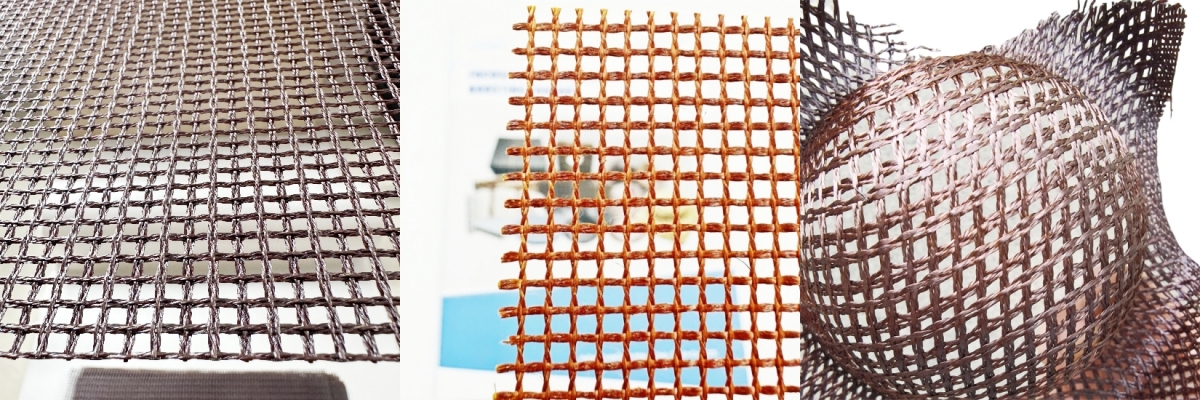

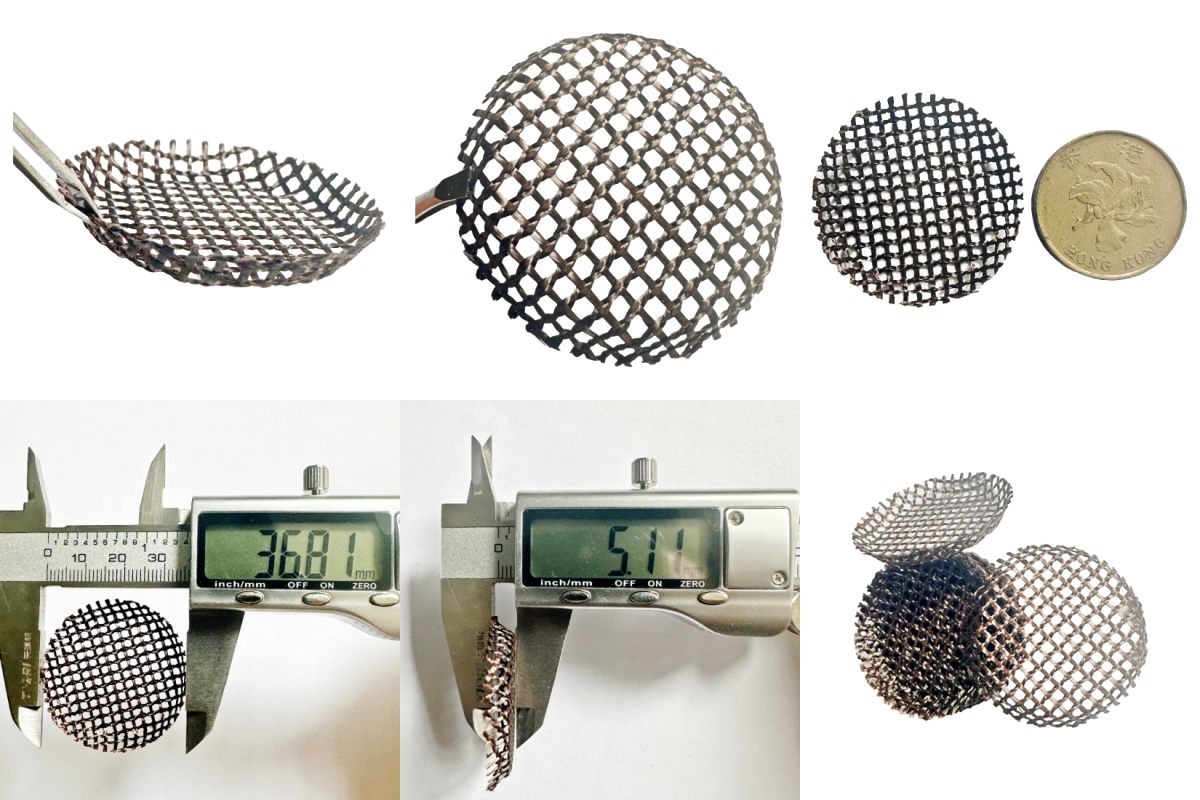

1. High Silica Fiberglass Filter Mesh is weaved by high silica fiberglass yarn and coated with special refractory coating. It can effectively remove slag, refractory particles and non-metallic inclusions from molten metals. Made from specially treated silica yarns, the thick type silica mesh filters are capable of withstanding pouring temperature up to 1700℃.

High Silica Fiberglass Filter Mesh is ideal for in-mold filtration of gray, malleable, white, compacted graphite and ductile cast irons, as well as copper-based metal alloys and many types of small scale steel casting filtration.

Besides the function of molten metal filters, it could be also used for riser knock-off or de-gating knock-off. Investment casters have also placed the perform cup shape filters in the wax mold gating system to filter metal at pattern entry.

2. Fiberglass Filter Mesh is woven with special high-twist & high-strength alkali-free fiberglass yarn, coated with special resin, carbonized by high temperature and special post-treatment. The maximum temperature resistance can reach 900 ℃.

Widely used in automobile and motorcycle wheels, cylinder pistons, aluminum rods, aluminum materials, aluminum ingots, aluminum plates and precision casting of all types of aluminum alloy casting.

New patented product "Smokeless & Odorless & Flameless" Effectively remove impurities, reduce turbulence and eliminate air bubbles, thereby improving the quality of castings and reducing costs. At the same time does not pollute the aluminum liquid and affect the chemical properties of the metal. Therefore, aluminum waste containing the filter mesh, aluminum liquid from sprue and the riser can be directly returned to the furnace for remelting, greatly reducing costs.

Let's see the following comparison table between steel filter mesh and fiberglass filter mesh, then you will have the answer!

| Material | Features | High-temperature chemical reaction with liquid | Fe Element | Contaminate liquid | Filter recycle | Liquid recycle and re-filter |

| Fiberglass yarn | Soft | No | No | No | Yes | Yes |

| Metal wire mesh | Hard | Yes | Yes | Yes | No | No |

Obviously:

1. There will be largely Fe element added to the aluminum castings when using wire mesh filter, which will be lower castings mechanical strength, especially for high quality standard, this is not acceptable.

2. Fiberglass filter mesh does not pollute the aluminum liquid and does not affect the chemical properties of the metal.

Therefore, aluminum waste containing fiberglass filter mesh, as well as aluminum liquid from sprue and the riser can be directly returned to the furnace for remelting, greatly reducing costs.

1. Difference between high silica and alkali-free fiberglass mesh

2. Metal wire mesh filters are NOT good for LPDC castings

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation