Feb. 07, 2026

Alumina foam ceramic is a kind of foam material made from high purity alumina. The foam ceramics have the characteristics of uniform porosity, high temperature resistance, heat shock resistance, wear resistance and chemical stability.

Widely used in casting processing, water treatment, chemical industry, environmental protection and other industries. It is the ideal liquid aluminum filter; Catalyst support, and good sound insulation, thermal insulation material. Product shapes, sizes, and voids PPI can be designed and manufactured on request.

Alumina Ceramic Foam Filter are produced with organic foam sponge with three-dimensional network structure and connected pores is used as the carrier, which is infiltrated into the special ceramic slurry with thixotropy, and a special rolling process is adopted to make the ceramic slurry evenly spread on the skeleton of the carrier, and then finished by roasting at high temperature after drying curing.

1. Alumina Ceramic Foam Filter have excellent thermal shock resistance, strength, and relatively high porosity and specific surface area.

2. They can filter and adsorb the smallest impurities mixed in the molten metal during casting, and utilize their unique rectification effect to achieve smooth and rapid laminar flow, preventing air bubbles from entering.

3. They are suitable for different refractoriness and pouring speeds in the casting industry.

4. They can significantly improve the quality of castings, facilitate cutting processing, thereby reducing tool wear and lowering manufacturing costs.

The model of the product is represented by the customary appellation P. The number in front of the English letter P represents the pore density of the product and corresponds to the pore uniformity.

For example, model 10P means a foam ceramic filter product with a pore uniformity of 7-13 pores on any 25.4mm length.

| Model | Pore density (Number of holes on any 25.4mm length) |

| 10p | 7~13 |

| 20p | 17~23 |

| 30p | 27~33 |

| 40p | 37~43 |

| 50p | 47~53 |

| 60p | 57~63 |

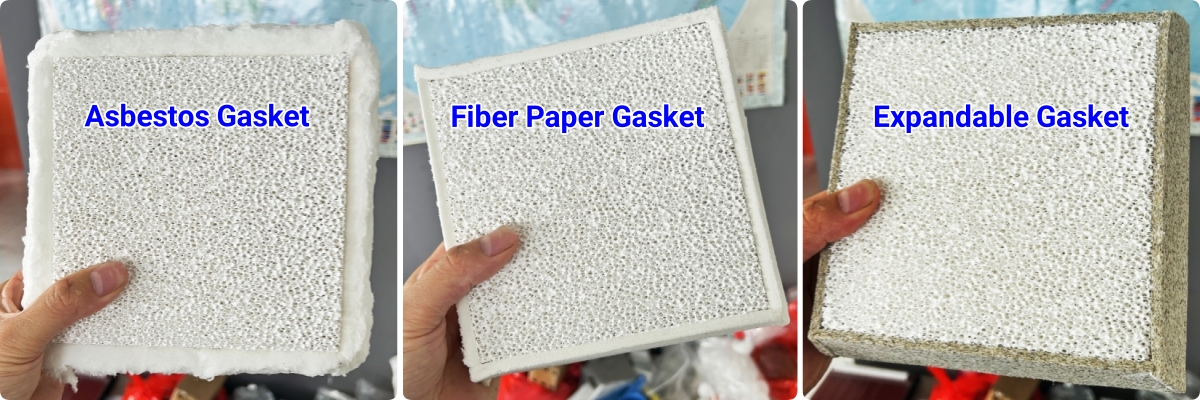

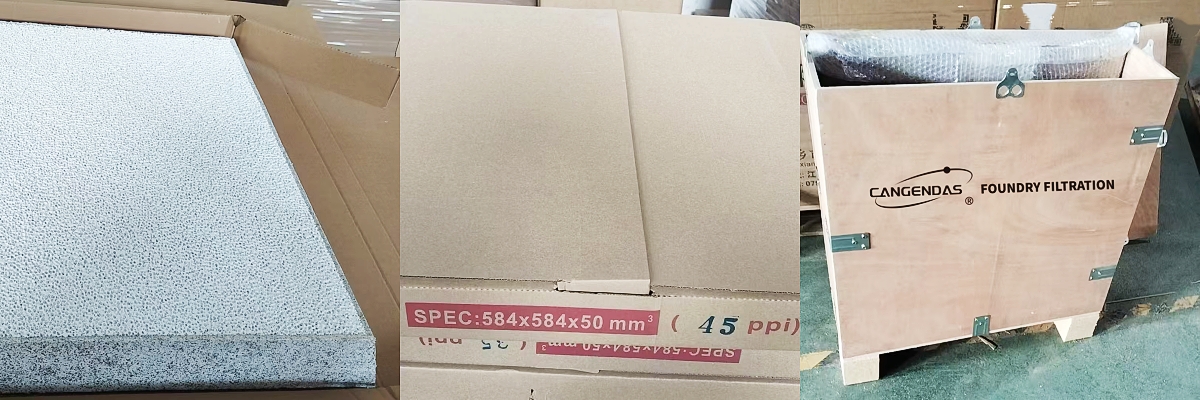

Today, 17x17x2 30ppi 23x23x2 45ppi with expanded cotton(expanded vermiculite) gaskets are ready for our Bahrain Client!

Pore uniformity is used to describe the difference between the actual number of pores per 25.4mm length in the filter plate product and the theoretically required number of pores.

The smaller the gap, the better the product quality.

If the gap is too large, the filter plate product will reduce the retention capacity of impurities or the filtration speed of the melt is too slow, which cannot meet the individual requirements of users in production. The size of the pore uniformity mainly depends on the foam used in the production of the filter plate. The pore uniformity of the foam is good, and the pore uniformity of the filter plate is good, so the selection of the foam is extremely important.

Round Fiberglass Filter Mesh For Recycled Aluminium Melt

Jan. 28, 2026

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation