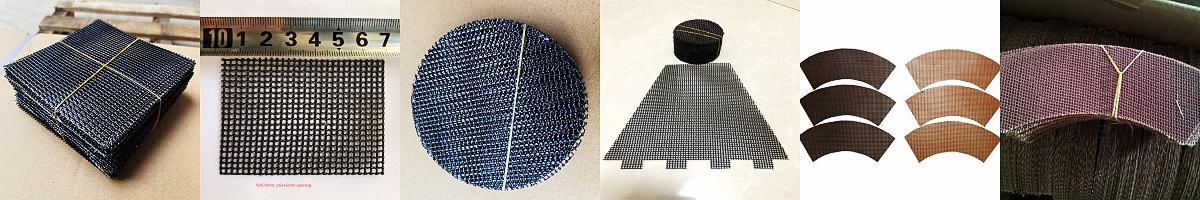

High temp fiberglass mesh filter is an ideal filter material for various metal melts.

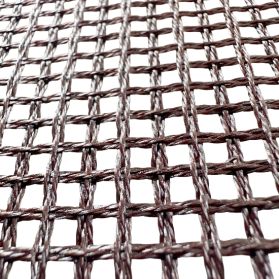

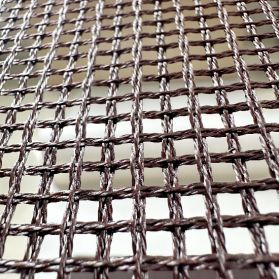

● Weaved with special high-twist & high-strength alkali-free fiberglass yarn.

● Coated by special resin.

● Special post-treatment under high temperature carbonized.

● The Max. temperature resistance can be reached 900 ℃.

● Smokeless & Odorless & Flameless during whole filtration process.

Cangchen Company's High Temp Carbonized Fiberglass Mesh Filter is a top-of-the-line product designed to provide effective and efficient air filtration in high-temperature environments. The filter is made of high-quality carbonized fiberglass material, which is known for its high-temperature resistance, durability, and excellent filtration properties.

Parameter

Cangchen Company's High Temp Carbonized Fiberglass Mesh Filter is a reliable and effective solution for air filtration needs in high-temperature industrial settings. With its exceptional filtration properties, durability, and high-temperature resistance, the filter ensures clean and safe air, improving workers' health and safety, enhancing productivity, and reducing maintenance costs.

High temp fiberglass mesh filter is widely used in automobile and motorcycle wheels, cylinder pistons, aluminum rods, aluminum materials, aluminum ingots, aluminum plates and precision casting of all types of aluminum alloy casting.

High Temp Fiberglass Mesh Filter Features and Functions:

● Effectively remove impurities, reduce turbulence and eliminate air bubbles from molten aluminium.

● Improving the quality of castings and reducing costs.

● Does not pollute the aluminum liquid and affect the chemical properties of the metal.

● The aluminium filtered by this mesh can be recycled again.

● It is environment-friendly products

● All shapes can be customized according to clients' requirements.

| Type | Alkali-free Fiberglass filtration mesh for aluminum |

| Work Temperature | 700-800℃ |

| Softening Temperature | 900℃ |

| Continuous Working Hours | <20Min.(700-800℃) |

| SiO2 | 58%-65% |

| Loss on ignition | ≤3% |

| Gas Emit | ≤30cm 3/g |

| Thickness | 0.35-0.5mm |

| Weight | 150-350 g/m2 |

| Hole Size | 0.8*0.8/1.0*1.0/1.2*1.2/1.5*1.5/2.0*2.0/2.5*2.5mm |

| Weave Pattern | Leno |

| Certificate | SDS |

| ISO9001:2015 |

High Temp Fiberglass Mesh Filter Key Features:

◆High-temperature resistance: The filter can withstand temperatures up to 900°C, making it ideal for use in industrial settings where high temperatures are common.

◆Excellent filtration: The carbonized fiberglass material provides exceptional filtration properties, effectively capturing even the smallest particles, including dust, dirt, and other contaminants.

◆Durability: The filter is designed to last long and withstand harsh industrial conditions, making it a reliable and cost-effective solution for air filtration needs.

◆Easy to install: The filter is easy to install and fits seamlessly into most industrial air filtration systems.

◆Wide application: The filter is suitable for use in a wide range of industries, including cement, power generation, steel, and petrochemical industries.

High Temp Fiberglass Mesh Filter Benefits:

◆Improved air quality: The filter's exceptional filtration properties ensure that the air in industrial settings is clean and free of harmful contaminants, protecting workers' health and safety.

◆Cost-effective: The filter's durability and long lifespan make it a cost-effective solution for air filtration needs, reducing maintenance costs and downtime.

◆Enhanced productivity: With clean and safe air, workers can work more efficiently and productively, resulting in improved overall performance.

◆The benefits of to use the fiberglass mesh filter to replace the traditional wire mesh filter

Filter Mesh Position:

The filter mesh can be cut into any specification, placed on the sprue parting surface of the box pressing, such as the combination of filter net and slag bag, its effect will be better.

1. Use area of filter net: F1 = F2 / AxB

● F1: the cross-sectional area of the casting system.

● F2: the original cross-sectional area of the casting system.

● A: the porosity of the filter screen, generally 50-60%.

● B: the filtration rate of filter screen, generally 60-80%.

Therefore, the cross-sectional area of the casting system is generally 2-4 times that of the casting system without the casting net.

2. Position of filter screen:

A. Place the filter under the sprue cup;

B. Placed on the parting surface under the sprue;

C. Three different positions on the lap surface of the runner.

3. Precautions for use of filter screen:

When the filter is used, it is necessary to guard against oblique pulling, wear and break. The size of the filter block should be greater than the size of the gate area 20-30mm. Handling, handling should be careful to handle, prevent extrusion, moisture.

A Guide on the Importance and Application of High Temperature Filters

The High Temp Fiberglass Mesh Filter is a type of air filter that is designed to be used in high-temperature environments. It is made from high-quality fiberglass material that is capable of withstanding temperatures of up to 800°C. This makes it an ideal solution for use in industrial settings where high temperatures are common.

The filter is constructed using a mesh design, which allows for excellent airflow while effectively capturing even the smallest particles in the air, such as dust, dirt, and other contaminants. The mesh design also provides the filter with a high dust-holding capacity, which means it can capture more particles before needing to be replaced.

The High Temp Fiberglass Mesh Filter is easy to install and can be used in a wide range of industries, including power generation, steel, cement, and petrochemical industries. Its high-temperature resistance, durability, and excellent filtration properties make it a reliable and cost-effective solution for air filtration needs.

Benefits of using the High Temp Fiberglass Mesh Filter include improved air quality, increased worker safety, and enhanced productivity. By effectively capturing harmful contaminants, the filter helps to protect workers' health and safety, while the clean air can help to improve overall productivity.

In conclusion, the High Temp Fiberglass Mesh Filter is an excellent solution for air filtration needs in high-temperature industrial settings. Its high-temperature resistance, durability, and excellent filtration properties make it a reliable and cost-effective choice for improving air quality, increasing worker safety, and enhancing productivity.

FAQ about High Temp Fiberglass Mesh Filter

Q: What is a High Temp Fiberglass Mesh Filter?

A: A High Temp Fiberglass Mesh Filter is an air filter that is designed to be used in high-temperature environments. It is made from high-quality fiberglass material that is capable of withstanding temperatures of up to 800°C.

Q: What are the benefits of using a High Temp Fiberglass Mesh Filter?

A: The benefits of using a High Temp Fiberglass Mesh Filter include improved air quality, increased worker safety, and enhanced productivity. By effectively capturing harmful contaminants, the filter helps to protect workers' health and safety, while the clean air can help to improve overall productivity.

Q: What industries can benefit from using a High Temp Fiberglass Mesh Filter?

A: The High Temp Fiberglass Mesh Filter can be used in a wide range of industries, including power generation, steel, cement, and petrochemical industries, where high temperatures are common and air quality is important.

Q: How does a High Temp Fiberglass Mesh Filter work?

A: The High Temp Fiberglass Mesh Filter works by using a mesh design that allows for excellent airflow while effectively capturing even the smallest particles in the air, such as dust, dirt, and other contaminants. The mesh design also provides the filter with a high dust-holding capacity, which means it can capture more particles before needing to be replaced.

Q: How often do High Temp Fiberglass Mesh Filters need to be replaced?

A: The frequency at which a High Temp Fiberglass Mesh Filter needs to be replaced will depend on a variety of factors, including the level of contaminants in the air and the size of the filter. However, the filter's high dust-holding capacity means it can capture more particles before needing to be replaced, making it a cost-effective solution for air filtration needs.

Q: Are High Temp Fiberglass Mesh Filters easy to install?

A: Yes, High Temp Fiberglass Mesh Filters are easy to install and can be used in most industrial air filtration systems. They are designed to fit seamlessly into existing systems, reducing downtime and minimizing disruption to industrial processes.

Application:

Industrial Furnaces: High temp fiberglass mesh filters are used in industrial furnaces to remove particulate matter from exhaust gases before they are released into the atmosphere.

Power Generation: These filters are used in power plants to remove fly ash and other particulate matter from exhaust gases generated by the combustion of fossil fuels.Such as:Filtration of Molten Aluminium.

Steel Production: High temp fiberglass mesh filters are used in steel production to remove impurities from molten steel before it is cast into various shapes.

Chemical Processing: These filters are used in chemical processing plants to remove impurities from various chemical solutions before they are used in various industrial processes.

Aerospace Industry: High temp fiberglass mesh filters are used in the aerospace industry to filter out impurities from hydraulic fluids and lubricants used in aircraft engines and other components.

Automotive Industry: These filters are used in the automotive industry to filter out impurities from lubricants and hydraulic fluids used in various components of vehicles.

High Silica Fiberglass Fabric Filter Mesh For Steel Iron And Copper (Thick Type)

High Silica Fiberglass Fabric Filter Mesh For Steel Iron And Copper (Thick Type)

Smokeless Odorless Fiberglass Casting Filter Mesh For Aluminum

Smokeless Odorless and Flameless Fiberglass Casting Filter Mesh For Aluminum liquid Filtration.

TF Combo Bag For Aluminum Ingot And Slab Filtration

Look forward to hearing from you:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation