The Fiberglass Cap Filter is woven with special high-twist & high-strength alkali-free fiberglass and special post-treatment. The maximum temperature resistance can reach 900 ℃.

The Glass Fiber Filter Netting Cap offers a wide range of applications and benefits in the aluminum casting industry. This specialized filter cap is designed to improve the quality and integrity of molten aluminum during the casting process.

Foundry Fiberglass Filter Hat is widely used in automobile and motorcycle wheels, cylinder pistons, aluminum rods, aluminum materials, aluminum ingots, aluminum plates and precision casting of all types of aluminum alloy casting.

Parameter

Fiberglass Cap Filter for Molten Aluminium Filtration by Cangchen, a premium solution designed to enhance the efficiency and quality of your aluminum casting processes. Our Fiberglass Filter Hats, also known as Glass Fiber Filter Netting Caps, are meticulously crafted to meet the rigorous demands of foundry operations.

At Cangchen, we understand the importance of customization, which is why we offer Fiberglass Cap Filter customization services. This allows you to tailor the filter hats to your specific requirements, ensuring optimal filtration performance and seamless integration into your production line.

| Type | Fiberglass Cap Filter For Aluminum |

| Models | Normal yellow(brown) color(without high temperature carbonization) |

| Black color(with high temperature carbonization) | |

| Work Temperature | 700-800℃ |

| Softening Temperature | 900℃ |

| Continuous Working Hours | <20Min.(700-800℃) |

| SiO2 | 58%-65% |

| Loss on ignition | ≤3% |

| Gas Emit | ≤30cm 3/g |

| Thickness | 0.35-0.5mm |

| Weight | 150-350 g/m2 |

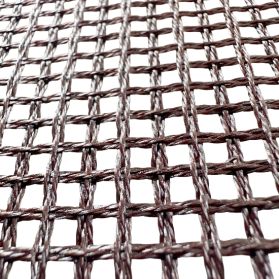

| Hole Size | 0.8*0.8/1.0*1.0/1.2*1.2/1.5*1.5/2.0*2.0/2.5*2.5mm |

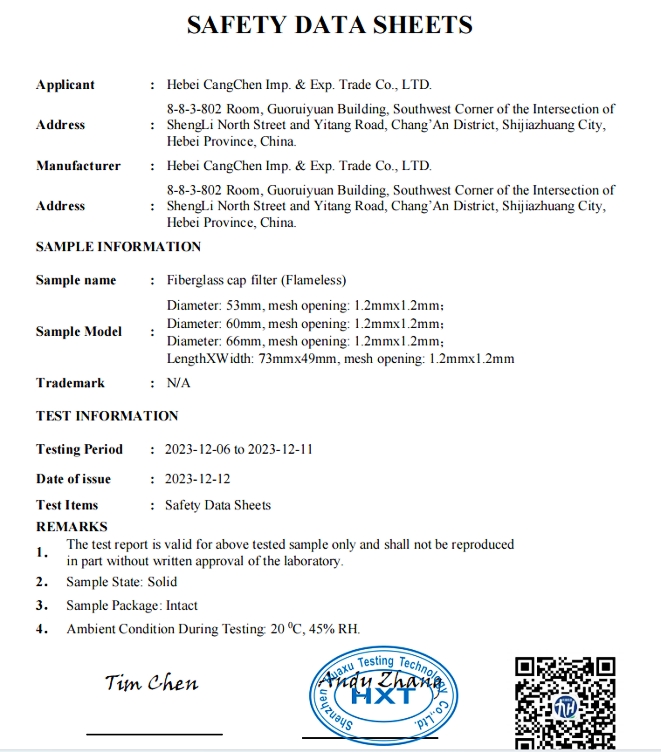

| Weave Pattern | Leno |

| Certificate | SDS |

| ISO9001:2015 |

Our Foundry Fiberglass Filter Hats are expertly engineered using high-quality fiberglass materials. The glass fiber filter netting cap is designed to effectively remove impurities, dross, and other contaminants from molten aluminum, resulting in improved casting quality and reduced defects.

The specialized design of our Glass Fiber Filter Netting Cap for Molten Aluminum Casting ensures efficient and consistent filtration throughout the casting process. It enables the removal of unwanted particles, such as oxides and inclusions, resulting in cleaner and more refined molten aluminum.

One of the key advantages of our custom Fiberglass Cap Filters is their versatility. They are suitable for various aluminum casting applications, including automotive, aerospace, and general industrial sectors. Whether you require filtration for large-scale production or smaller-scale operations, our Fiberglass Cap Filters can be customized to meet your specific needs.

With Cangchen's Fiberglass Cap Filter for Molten Aluminium Filtration, you can expect exceptional durability, longevity, and reliable performance. Our filters are designed to withstand the high temperatures and harsh conditions of the aluminum casting process, ensuring consistent and efficient filtration over extended periods.

Experience the benefits of our Fiberglass Cap Filters and elevate your aluminum casting processes to new heights of quality and efficiency. Contact us today to discuss your filtration requirements and take advantage of our custom solutions tailored to your unique needs.

As a filter equipment often used in industrial production, Cap Filter plays an important role in metal smelting industry. In recent years, with the development of industry, its application is more and more wide. A qualified screen manufacturer should first understand the needs of users. Only by understanding the market, can we occupy the market. Through the understanding of the market and analysis, can effectively improve the product publicity effect.Secondly, product characteristics are one of the important factors affecting the development of cap filter manufacturers. Maintain product quality and characteristics, timely understanding of the market, change the marketing strategy, so that consumers better understand the characteristics of the equipment.

1. First of all, because of the shortage of resources, it is imperative to reduce the waste of resources in the metal industry. Through the use of cap filter, can effectively reduce more than half of the slag, impurities caused by the waste phenomenon. This is also the main reason for the wide use of filters, is also the main trend.

2. It can effectively remove non-metallic inclusions in liquid metal, which is also a big use of cap filter. Through the use of filter, can significantly improve the casting structure and mechanical properties, so that the casting quality is higher, better quality, reduce the rejection rate, reduce tool wear.

Casting filter is not only used to reduce casting porosity, but also can effectively reduce casting surface defects and increase process yield. It can effectively screen and adsorb small pre-slag, so that the quality of metal castings is better, the performance is better, to create high-quality castings.

Fiberglass Cap Filters can be customized according to clients' own requirements, if you are interested in this, please contact us or leave a message, exact quotation and free samples are sent to you as quicly as possible!

Application:

Impurity Removal: The Glass Fiber Filter Netting Cap effectively captures and removes impurities, such as oxides, slag, and dross, from the molten aluminum. This helps to enhance the purity and cleanliness of the aluminum, resulting in higher-quality castings.

Inclusion Reduction: By employing the Glass Fiber Filter Netting Cap, the occurrence of unwanted inclusions in the molten aluminum can be significantly reduced. The cap's fine netting structure traps and prevents the entry of particles, ensuring a smoother and more refined casting process.

Defect Minimization: The use of the Glass Fiber Filter Netting Cap helps to minimize casting defects, such as porosity and surface irregularities. By filtering out impurities and reducing the chances of inclusions, the cap contributes to the production of defect-free and high-integrity aluminum castings.

Enhanced Flow Control: The netting design of the Glass Fiber Filter Netting Cap enables efficient control of the flow of molten aluminum during the casting process. This facilitates better mold filling and metal distribution, resulting in improved casting outcomes and dimensional accuracy.

Versatile Casting Applications: The Glass Fiber Filter Netting Cap is suitable for various molten aluminum casting applications, including automotive components, aerospace parts, industrial machinery, and more. Its versatility makes it an essential tool for achieving consistent and high-quality castings across different industries.

Increased Productivity: By ensuring cleaner and purer molten aluminum, the Glass Fiber Filter Netting Cap helps to minimize downtime and rework caused by casting defects. This leads to increased productivity, reduced scrap rates, and improved overall operational efficiency.

High Silica Fiberglass Fabric Filter Mesh For Steel Iron And Copper (Thick Type)

High Silica Fiberglass Fabric Filter Mesh For Steel Iron And Copper (Thick Type)

Fiberglass Cap Filter For Aluminium Pistons Filtration

Smokeless Odorless Fiberglass Casting Filter Mesh For Aluminum

Smokeless Odorless and Flameless Fiberglass Casting Filter Mesh For Aluminum liquid Filtration.

TF Combo Bag For Aluminum Ingot And Slab Filtration

Look forward to hearing from you:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation