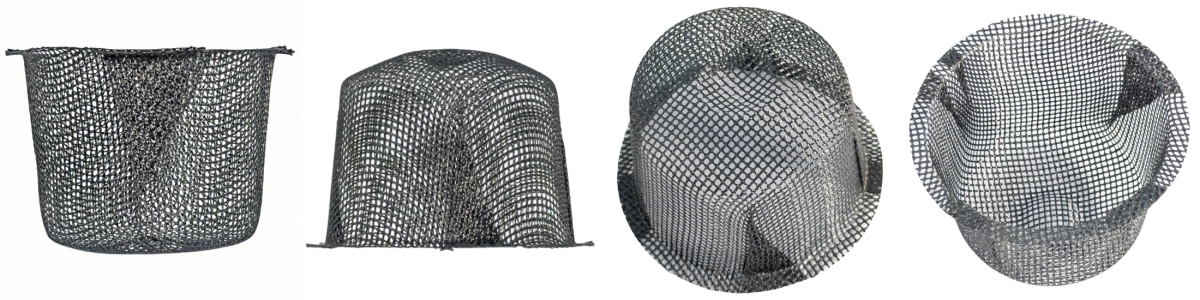

The cap-style is woven with special high-twist & high-strength alkali-free fiberglass and special post-treatment. The maximum temperature resistance can reach 900 ℃.

Cap type fiberglass filter mesh is usually a network structure, which is a non-metallic liquid metal purification device with the required mesh opening. Its porosity is higher, the slag collection surface area is larger, and it can reduce the the Reynolds number of the mesh metal surface flowing through the cast filter, then it can make the filler be more stable and reduce the production of secondary oxidation slag in the mold.

Fiberglass Cap Filter is widely used in automobile and motorcycle wheels, cylinder pistons, aluminum rods, aluminum materials, aluminum ingots, aluminum plates and precision casting of all types of aluminum alloy casting.

Parameter

At Cangchen, we take immense pride in presenting our cutting-edge product, the Fiberglass Cap Filter. Designed to revolutionize filtration processes across various industries, our Fiberglass Cap Filter delivers exceptional performance and durability.

The Fiberglass Cap Filter is specifically engineered using advanced fiberglass filtration technology, ensuring superior filtration efficiency and enhanced productivity. Our product is meticulously crafted to meet the stringent demands of industries such as aluminum production, metal casting, and other high-temperature applications.

| Type | Fiberglass Cap Filter For Aluminum |

| Work Temperature | 700-800℃ |

| Softening Temperature | 900℃ |

| Continuous Working Hours | <20Min.(700-800℃) |

| SiO2 | 58%-65% |

| Loss on ignition | ≤3% |

| Gas Emit | ≤30cm3/g |

| Thickness | 0.35-0.5mm |

| Weight | 150-350 g/m2 |

| Hole Size | 0.8*0.8/1.0*1.0/1.2*1.2/1.5*1.5/2.0*2.0/2.5*2.5mm |

| Weave Pattern | Leno |

| Certificate | SDS |

| ISO9001:2015 |

Fiberglass Cap Filters can effectively remove impurities, reduce turbulence and eliminate air bubbles, thereby improving the quality of castings and reducing costs. At the same time does not pollute the aluminum liquid and affect the chemical properties of the metal. Therefore, aluminum waste containing the filter mesh, aluminum liquid from sprue and the riser can be directly returned to the furnace for remelting, greatly reducing costs.

1.First of all, because of the shortage of resources, it is imperative to reduce the waste of resources in the metal industry. Through the use of cap filter, can effectively reduce more than half of the slag, impurities caused by the waste phenomenon. This is also the main reason for the wide use of filters, is also the main trend.

2.It can effectively remove non-metallic inclusions in liquid metal, which is also a big use of cap filter. Through the use of filter, can significantly improve the casting structure and mechanical properties, so that the casting quality is higher, better quality, reduce the rejection rate, reduce tool wear.

3.Casting filter is not only used to reduce casting porosity, but also can effectively reduce casting surface defects and increase process yield. It can effectively screen and adsorb small pre-slag, so that the quality of metal castings is better, the performance is better, to create high-quality castings.

At Cangchen, we are committed to delivering exceptional value to our customers. Our Fiberglass Cap Filter is competitively priced, reflecting its outstanding quality, performance, and durability. We offer flexible pricing options, ensuring affordability without compromising on product excellence.

Upgrade your filtration process with our innovative Fiberglass Cap Filter. Unlock the potential for improved productivity, higher-quality outputs, and enhanced operational efficiency. Trust Cangchen to provide you with the industry-leading solution you need for your filtration requirements.

Buy your Fiberglass Cap Filter today and witness the transformative power of advanced fiberglass filtration technology!

Unparalleled Filtration Capability: Our Fiberglass Cap Filter incorporates a high-quality fiberglass mesh, known for its exceptional filtration properties. It effectively captures impurities and contaminants, guaranteeing a cleaner and purer end product.

Enhanced Durability: Crafted from high-strength fiberglass materials, our Fiberglass Cap Filter is built to withstand extreme temperatures, chemical exposure, and mechanical stress. This durability ensures a longer lifespan, reducing the need for frequent replacements and minimizing downtime.

Optimal Performance: The unique design of our Fiberglass Cap Filter maximizes airflow while maintaining excellent filtration efficiency. This enables a steady and consistent flow of molten aluminum or other liquids, resulting in improved production output and reduced operational costs.

Easy Installation and Maintenance: The Fiberglass Cap Filter is designed for hassle-free installation and maintenance. Its user-friendly design allows for quick and seamless integration into existing filtration systems, reducing downtime and optimizing workflow efficiency.

Cost-Effective Solution: Our Fiberglass Cap Filter offers an exceptional value proposition by providing a cost-effective filtration solution. It minimizes material wastage, lowers energy consumption, and decreases the need for frequent maintenance, resulting in substantial cost savings for your operations.

We offer a wide range of Fiberglass Cap Filter variants to cater to diverse industry requirements. Whether you need a specific mesh size, dimensions, or custom configurations, our team is dedicated to fulfilling your unique filtration needs.

To order your Fiberglass Cap Filter, simply visit our website or contact our dedicated sales team. Our responsive customer service representatives will guide you through the ordering process, ensuring a seamless experience from start to finish.

We can customize all shapes of cap filters according to your own drawings and samples, if interested, please contact us or leave a message.

Application:

Aluminum Production: The Fiberglass Cap Filter is extensively used in the aluminum industry for the filtration of molten aluminum. It effectively removes impurities, such as dross, oxides, and non-metallic inclusions, ensuring a higher-quality aluminum end product.

Metal Casting: In metal casting processes, the Fiberglass Cap Filter is employed to filter molten metals, including iron, steel, copper, and other alloys. It helps eliminate unwanted contaminants and solid particles, resulting in improved casting quality and reduced defects.

Foundries: Foundries utilize the Fiberglass Cap Filter for filtration in processes such as sand casting, investment casting, and die casting. It aids in maintaining the purity of molten metals and alloys, leading to enhanced mold filling, reduced porosity, and improved mechanical properties of castings.

Welding Industry: The Fiberglass Cap Filter is commonly used in welding applications to capture and filter welding fumes and particulate matter. It ensures a cleaner and healthier working environment by effectively trapping hazardous particles and reducing airborne pollutants.

Chemical Processing: Fiberglass Cap Filters are utilized in chemical processing industries for the filtration of corrosive liquids and chemicals. The high-quality fiberglass mesh provides excellent chemical resistance and ensures the removal of impurities, ensuring product purity and process efficiency.

Oil and Gas: In the oil and gas sector, the Fiberglass Cap Filter plays a vital role in the filtration of fluids, including crude oil, natural gas, and petroleum derivatives. It helps remove contaminants, sediments, and solid particles, safeguarding equipment and ensuring the smooth operation of refining and processing facilities.

Power Generation: The Fiberglass Cap Filter is employed in power plants for filtration applications involving cooling water systems, boiler feedwater, and other process fluids. It assists in maintaining the cleanliness of the water and protecting critical equipment from damage caused by suspended solids.

Automotive Industry: Automotive manufacturers utilize the Fiberglass Cap Filter in paint booths and surface treatment processes to capture overspray and airborne particles. It ensures a cleaner working environment, reduces paint defects, and improves the overall quality of finished automotive components.

Silica Mesh Filter For Foundry Casting Metal Filtration

Silica Mesh Filter For Molten Aluminium, Steel, Iron and Copper Filtration.

Fiberglass Cap Filter For Aluminium Pistons Filtration

Smokeless Odorless Fiberglass Casting Filter Mesh For Aluminum

Smokeless Odorless and Flameless Fiberglass Casting Filter Mesh For Aluminum liquid Filtration.

TF Combo Bag For Aluminum Ingot And Slab Filtration

Look forward to hearing from you:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation