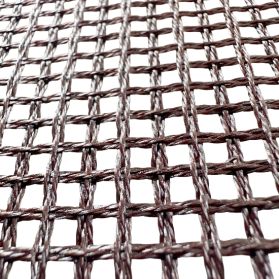

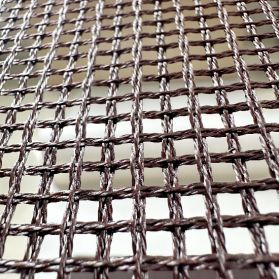

High silica fiberglass mesh filters are weaved by high silica fiberglass yarn and coated with special refractory coating.

High Silica Fiberglass Filter Mesh is ideal for in-mold filtration of gray, malleable, white, compacted graphite and ductile cast irons, as well as non-ferrous aluminum and copper-based metal alloys and many types of small scale steel casting filtration.

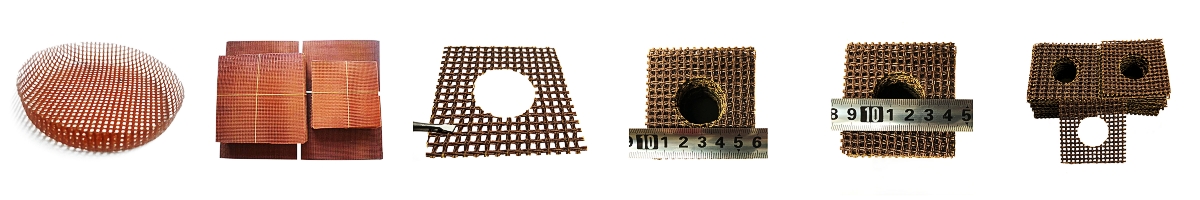

Besides the function of molten metal filters, it could be also used for riser knock-off or de-gating knock-off. Investment casters have also placed the perform cup shape filters in the wax mold gating system to filter metal at pattern entry.

The filters are capable of withstanding pouring temperature up to 1620℃.

Parameter

The CangChen Silica Mesh Filter for Foundry is engineered for exceptional performance in foundry applications, ensuring high-quality filtration of impurities from molten metal. Designed with high-silica fiberglass yarn, this filter is a trusted solution among foundry molten metal filters, providing an optimal balance of durability and efficiency.

The Silica Mesh Filter for Foundry effectively removes slag, refractory particles, and non-metallic inclusions from molten metals. Its advanced design improves metal fluidity and distribution, reducing turbulence and ensuring that casting processes yield superior quality outcomes.

Click here to view all of our industrial fiberglass filter!

It can effectively remove slag, refractory particles and non-metallic inclusions from molten metals.

Made from specially treated silica yarns, the thick type silica mesh filters are capable of withstanding pouring temperature up to 1620℃.

Silica mesh filter are ideal for in-mold filtration of gray, malleable, white, compacted graphite and ductile cast irons, as well as non-ferrous aluminum and copper-based metal alloys and many types of small scale steel casting filtration.

Besides the function of molten metal filters, it could be also used for riser knock-off or de-gating knock-off.

Investment casters have also placed the perform cup shape filters in the wax mold gating systerm to filter metal at pattern entry.

Advantages

1. Low cost and easy to use

2. Improves fluidity and metal distribution

3. Removes micron sized inclusions and impurities

4. Can be used with existing pattern equipment

5. Reduce turbulence

6. Minimize gating system to reduce cost

| Type | High Silica Fiberglass Filter Mesh For Steel Iron And Copper | |

| Work Temperature | ≤1620℃ | |

| Softening Temperature | 1700℃ | |

| Continuous Working Hours | <10 Min.(1400-1450℃) | |

| <4 Min.(1450-1560℃) | ||

| <15 Seconds.(1560-1620℃) | ||

| Gas Emit | ≤60cm 3/g | |

| Thickness | 1.5mm | |

| Weight | 520-580 g/m2 | |

| Weave Pattern | Mock Leno | |

| Hole Size | 1.5*1.5/2.0*2.0/2.5*2.5mm | |

| Mesh Opening Chosen | White Iron | 1.5mm |

| Gray Iron(Pour weight≤100kgs ) | 1.5mm | |

| Gray Iron(Pour weight≥100kgs ) | 2.0mm | |

| Malleable Iron | 1.5mm | |

| Compacted Graphite Iron | 1.5mm & 2.0mm | |

| Ductile Iron(Pour weight ≤ 100kg) | 2.0mm | |

| Ductile Iron(Pour weight ≥ 100kg) | 2.5mm | |

| Carbon Steel | 1.5mm | |

| Stainless Steel | 1.5mm | |

| Brass | 1.5mm & 2.0mm | |

| Bronze | 1.5mm & 2.0mm | |

| Certificate | MSDS | |

| ISO9001:2015 | ||

Key Points of Usage

1. Use area of filter net: F1 = F2 / AxB

● F1: the cross-sectional area of the casting system.

● F2: the original cross-sectional area of the casting system.

● A: the porosity of the filter screen, generally 50-60%.

● B: the filtration rate of filter screen, generally 60-80%.

Therefore, the cross-sectional area of the casting system is generally 2-4 times that of the casting system without the casting net.

2. Position of filter screen:

● Place the filter under the sprue cup;

● Placed on the parting surface under the sprue;

● Three different positions on the lap surface of the runner.

Constructed from high silica fiberglass yarn, the Silica Mesh Filter for Foundry can withstand pouring temperatures up to 1620℃. This robust performance makes it ideal for in-mold filtration across a range of casting processes including gray, malleable, white, compacted graphite, and ductile cast irons.

Featuring a soft uncoated or half-rigid, thin resin-coated structure, this Silica Mesh Filter for Foundry is remarkably versatile. Shipped in rolls for convenient storage and cutting, it adapts seamlessly to out-mold applications on launders, furnace sprues, ladle transfers, and can even be integrated into gating systems and cores.

By eliminating inclusions such as ceramic chips and effectively capturing micron-sized impurities, this filter elevates the overall quality of metal castings. Its use in foundry molten metal filters ensures that each casting process benefits from reduced gating system complexity and lowered production costs.

Available in sizes from 30x30mm/D30mm to 900x1000mm, the Silica Mesh Filter for Foundry comes in a variety of shapes including round, square, and rectangular, with custom configurations available upon request. These flexible dimensions meet the diverse needs of modern casting techniques and equipment setups.

To maintain optimal performance, avoid direct high-flow impact from molten metal and ensure careful handling to prevent abrasion, fracture, or extrusion. This Silica Mesh Filter for Foundry is recommended for in-mold filtration in sand casting, gravity casting, shell mold casting, and other advanced foundry applications.

Experience the unmatched reliability and quality of CangChen Silica Mesh Filter for Foundry—a premium refractory cloth filter designed to elevate every aspect of the casting process. Embrace the excellence of our Silica Mesh Filter for Foundry and transform your foundry operations.

FAQ

1.What is high silica fiberglass filter mesh?

High silica fiberglass filter mesh is a high temperature resistant inorganic fiber material. It removes impurities from molten metal. If you need to do small castings, choosing a high-silica glass fiber filter can fully meet your needs.

2.Can high silica fiberglass filter mesh withstand high temperatures?

The high-silica glass fiber filter can work continuously at a temperature of 1000 °C and short-term temperature resistance of 1400 °C. It is an excellent inorganic material with high-temperature resistance, heat insulation, and heat preservation.

3.How is high silica fiberglass filter mesh made?

The high silica glass fiber filter mesh is a filter mesh woven with high-silica glass fiber. The surface of the high silica glass fiber filter mesh is coated with a high-temperature resistant coating. Finally, a filter mesh with a certain rigidity is produced.

4.How to use high silica fiberglass filter mesh?

The high silica fiberglass filter mesh can be used to filter and purify impurities in metal smelting and casting.

If you are interested in the Fiberglass Filter For Steel, welcome to contact us.

Application:

Filtration of Molten Steel

Iron

Copper and Aluminium

High Silica Fiberglass Fabric Filter Mesh For Steel Iron And Copper (Thick Type)

High Silica Fiberglass Fabric Filter Mesh For Steel Iron And Copper (Thick Type)

Smokeless Odorless Fiberglass Casting Filter Mesh For Aluminum

Smokeless Odorless and Flameless Fiberglass Casting Filter Mesh For Aluminum liquid Filtration.

TF Combo Bag For Aluminum Ingot And Slab Filtration

Look forward to hearing from you:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation