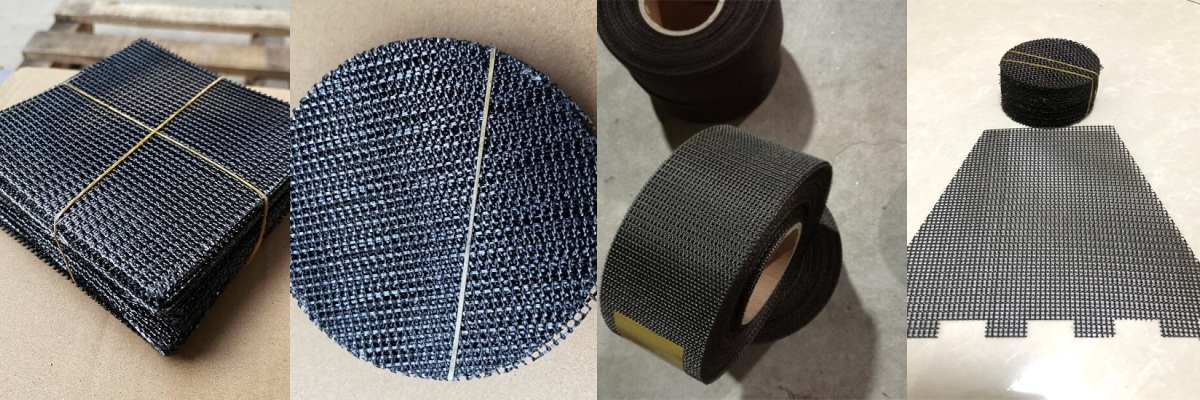

New patented product "Smokeless & Odorless & Flameless" fiberglass filter mesh is woven with special high-twist & high-strength alkali-free fiberglass yarn and special post-treatment.

It is carbonized by high temperature and coated with special resin. The maximum temperature resistance can reach 900 ℃.

Widely used in automobile and motorcycle wheels, cylinder pistons, aluminum rods, aluminum materials, aluminum ingots, aluminum plates and precision casting of all types of aluminum alloy casting.

Parameter

New patented product "Smokeless & Odorless & Flameless fiberglass filter mesh" is widely used for filtration of aluminum liquid casting.

It can effectively remove impurities, reduce turbulence and eliminate air bubbles, thereby improving the quality of castings and reducing costs.

At the same time does not pollute the aluminum liquid and affect the chemical properties of the metal.

Therefore, aluminum waste containing the filter mesh, aluminum liquid from sprue and the riser can be directly returned to the furnace for remelting, greatly reducing costs.

Features and Functions:

1. Carbonized by High Temperature

2. Coated with special resin

3. Smokeless & Odorless & Flameless

4. Effectively remove impurities, reduce turbulence and eliminate air bubbles from molten aluminium

5. Improving the quality of castings and reducing costs

6. The aluminium filtered by this mesh can be recycled again

7. It is environment-friendly products

8. All shapes can be customized according to clients' requirements

| Type | Fiberglass Filter Cloth in roll for aluminum filtration | |

| Yarn type | E-glass fiberglass | |

| Weave type | Leno & plain | |

| Width/roll | 0.9m/1.0m ± 1cm and customized | |

| Length/roll | 100m/150m/200m and customized | |

| Thickness | 0.35-0.6mm | |

| Weight | 150-350g/m2 | |

| Mesh opening | 0.8*0.8/1.0*1.0/1.2*1.2/1.5*1.5/2.0*2.0/2.5*2.5mm and customized | |

| Coating | No Coating | White color and soft fabric |

| Coating with special resin | Brown color and hardness fabric | |

| Work Temperature | 700-900℃ | |

| Softening Temperature | 900℃ | |

| Continuous Working Hours | <20Min.(700-800℃) | |

| Gas Emit | ≤30cm 3/g | |

| Loss on ignition | ≤3% | |

| SiO2 | 58%-65% | |

| Certificate | SDS | |

| ISO9001:2015 | ||

Key Points of Usage:

1. Use area of filter net: F1 = F2 / AxB

● F1: the cross-sectional area of the casting system.

● F2: the original cross-sectional area of the casting system.

● A: the porosity of the filter screen, generally 50-60%.

● B: the filtration rate of filter screen, generally 60-80%.

Therefore, the cross-sectional area of the casting system is generally 2-4 times that of the casting system without the casting net.

2. Position of filter screen:

● Place the filter under the sprue cup;

● Placed on the parting surface under the sprue;

● Three different positions on the lap surface of the runner.

Application type:

● Filter cloth in roll (white & brown, without/with coating) : It can be fixed in the aluminum liquid flow tank, used for aluminum ingot, aluminum rod, aluminum strip and other continuous casting workshop to purify aluminum liquid.

● Cutting mesh (brown, coated with resin): Square, round, fan and other heteroideus mesh cutted just according to client’s requirements. Used for filtering aluminum castings and placed in the gating system.

● Cylinder, cap and other special shapes (brown or black, coated with resin or carbonized): used for low pressure casting, such as aluminum alloy wheels, engine cylinder head and so on.

● Smokeless (black carbonization treatment): no combustion, smokeless, low gas output during the filtration process, for high quality requirements of casting production, such as aluminum alloy piston.

Application:

Used in wheels, cylinder and pistons of automobile and motorcycle.

Used in aluminum rods, aluminum materials, aluminum ingots, aluminum plates.

Used in precision casting of all types of aluminum alloy casting.

Look forward to hearing from you:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation