Fiberglass Filtration & Shunt Combo Bag, also named Fiberglass thermally fused shunt combo bag/TF Combo Bag, weaved by special high-twist & high-strength alkali-free fiberglass yarn(E-fiberglass), special post-treatment, coated with resin and carbonized by high temperature(Very important point), its withstand temperature up to 1000 °C.

Main Function:

● Apply to filter and evenly distribute molten aluminum in molds.

● Apply to filter large diameter aluminum ingot and billet, rectangular aluminium slab, and aluminum-alloy casting parts.

Three Main Features:

● New environmental protection material, does not burn during whole use process, no harm to human body.

● Advanced production equipment, warp and weft standard for base cloth, high temperature resistant coating mesh uniform, the finished product is exquisitely made without burrs.

● Both sides of the bag adopt square hole fixing device technology, more convenient operation and improve the working rate.

How To Use:

● Click here to get more introduction of user manual.

Parameter

The CangChen Fiberglass Filtration Shunt Combo Bag For Molten Aluminium sets the standard for high-performance molten aluminum processing. This specialized product seamlessly integrates both distribution and filtration functions, ensuring efficient metal flow and impurity removal.

The Fiberglass Filtration Shunt Combo Bag For Molten Aluminium is a state-of-the-art refractory material engineered specifically for molten aluminum. Woven from high-twist fiberglass yarns, it withstands extreme temperatures (up to 1,200°C) and pressure, making it ideal for rolling slab castings, alloy production, and other critical applications.

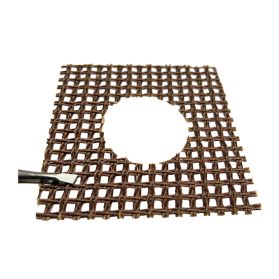

Much tighter fabric surround the small fiberglass woven frame inside for Fiberglass Filtration & Shunt Combo Bag. This bag can filter the molten aluminium and distribute the flowing molten fluid which can make fluid smooth and steady and no gas inside. To ensure the quality of alloy.

High-Temperature Resistance: Endures temperatures up to 1,200°C to maintain integrity during molten aluminum processing.

Reinforced Structure: Crafted with high-twist fiberglass yarns, the design resists flattening or distortion under pressure.

Self-Hardening Design: Automatically hardens upon contact with molten metal, stabilizing the mold path and enhancing distribution efficiency.

Customizable Shapes: Available in pressed filter cups, tailored mesh designs, and versatile forms for varied industrial requirements.

Breathability: Reduces melt turbulence, thereby ensuring a consistent and smooth metal flow.

Production Details:

Fixing Bags & Sewing Process:

Technical Data Sheet:

| Type | Fiberglass Filtration & Shunt Combo Bag For Aluminum |

| Work Temperature | ≤1000℃ |

| Melting Point | 1100℃ |

| Color | White, Brown and Yellow |

| Normal Dimensions | 120x150x300mm, 120x150x330mm, 140x150x450mm, |

| Mesh Openning | 5mesh, 7mesh, 8mesh, 9mesh, 10mesh, 12mesh, 14mesh, 16mesh, 18mesh, 20mesh, 25mesh, and special specifications can be customized. |

| Application | Filtration & Shunt For All Aluminium and aluminium alloy products. |

| Work Time: | 4hours when flow ≤10 kg/min. |

| 1.5hours when flow ≤120 kg/min. | |

| Tensile Strength | 8KGS |

| Filter fineness | 5-50(μm) |

| Filter area | 100(m2) |

| OEM | Logo, Size and Shape of fiberglass filter bag, according to customer's requirement, and also drawing or samples. |

| Certificate | MSDS |

| ISO9001:2015 |

Ideal for large-particle filtration, the Fiberglass Filtration Shunt Combo Bag For Molten Aluminium is used in trough socks, channel bags, launder windsocks, and spout socks. Its versatility extends to high-end aluminum alloy slab castings and precision alloy production. In addition, specialized filter pouches are incorporated to meet niche industrial requirements, ensuring optimal performance in every casting scenario.

● Apply to filter and evenly distribute molten aluminum in molds.

● Used in sand casting, permanent mold, shell mold, draw mold and investment casting, which can remove impurities, reduce turbulence, eliminate air bubbles, thereby improve casting quality and reduce production costs.

● Apply to filter large diameter aluminum ingot and billet, rectangular aluminium slab, and aluminum-alloy casting parts.

Main Functions:

● Helps to reduce the turbulence of metal flow and improve the temperature distribution throughout the mold volume.

● Filter the molten metal and decrease in non-metallic inclusions and oxide films in the liquid metal.

● Improve mechanical quality of aluminum casting product.

● Improve the hardness of aluminum casting product with more average surface hard and bending strength.

● Comparing to other filter bags, it does not affect the component of aluminum alloy, and with good filtration effect, high temperature resistance, high strength, excellent acid and alkali resistance, non-stick aluminum, non-slagging, non-peeling, as well as easy installation.

Bags Compared Before & After Use:

Main purposes of using TF Combo Bags:

1. The aluminum liquid is divided to two ends of ingot through the bags, this process will determines the temperature distribution around crystallizer device. And the metallographic structure of the cured aluminum alloy ingot will be affected by the temperature distribution.

2. To keep and leave the oxide in the bag, reduce the aluminium liquid flow and filter out all the large particles that mainly include alumina, chloride and titanium, boron, magnesium oxide and large resistant material shed.

TF Combo Bag is one of process in contact with aluminum liquid in casting foundry, so it is quite important. It is the key to achieve the casting quality standards of aluminum and aluminum alloy flat ingot if bags and skimming ring are used together.

The Fiberglass Filtration Shunt Combo Bag For Molten Aluminium offers several benefits:

Environmentally Safe: It produces no fire, toxic gases, or black ash, minimizing pollution during casting.

Corrosion Resistance: Its advanced material resists molten aluminum corrosion, reducing mold sticking and enhancing casting surface quality.

Energy Efficiency: The product’s excellent heat retention minimizes heat loss and prevents overheating.

Defect Reduction: Effectively eliminates oxide inclusions, porosity, and excessive iron content, improving the mechanical properties of the final castings.

Cost-Effective: By lowering scrap rates and improving ductility, it enhances overall production efficiency.

Material: High-twist fiberglass yarn woven for enhanced durability

Temperature Endurance: Up to 1,200°C

Design Options: Available as pressed filter cups, tailored mesh designs, and versatile configurations for custom solutions

Manufacturer: Kingwell Fibre Materials Co., Ltd. (Jiangsu, China)

Embrace the reliability and advanced technology of the CangChen Fiberglass Filtration Shunt Combo Bag For Molten Aluminium to optimize your molten aluminum processes. With its robust construction, customizable design, and integrated filtration efficiency, this product ensures superior performance from start to finish—ultimately elevating every facet of your foundry operations, including the refined Filter Pouch solutions. CangChen remains the optimal choice for precision and quality in high-end casting, right through to the very end of your production cycle.

FAQ From Our Clients:

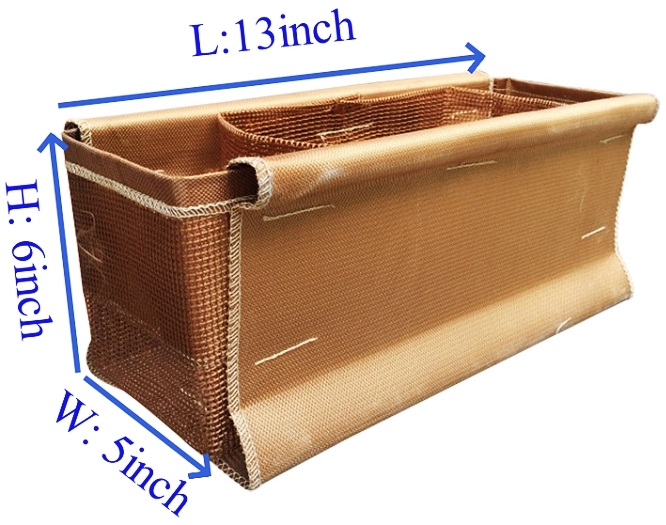

1. What is the dimension of this bag used for alumium casting filtration?

Usually out dimensions: 13"x5"x6", mesh openning is 2.5x2.5mm

2. Can we get free samples to test?

Of course, we will provide free samples to test, but freight need to be paid by clients.

3. What is the productivity of this bag?

Usually, 10,000pieces per month, if urgent orders, 1-30,0000 pieces also can be produced per month.

4. What is the certification of company?

ISO9001:2015

Application:

Filter molten aluminum in molds.

Distribute evenly molten aluminum in molds.

To filter large diameter aluminum ingot and billet, rectangular aluminium slab, and aluminum-alloy casting parts.

Fiberglass Mesh Filter For Molten Metal Casting

High Temperature Carbonized Fiberglass Mesh Filter For Foundry Filtration

Fiberglass Cap Filter For Aluminium Pistons Filtration

Smokeless Odorless Fiberglass Casting Filter Mesh For Aluminum

Smokeless Odorless and Flameless Fiberglass Casting Filter Mesh For Aluminum liquid Filtration.

Look forward to hearing from you:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation