Our High Silica Fiberglass Fabric Filter offers reliable filtration efficiency, removing impurities, and particulate matter from air or liquid streams. It is particularly well-suited for steel and iron manufacturing, where the filtration of hot gases, dust, and pollutants is crucial to maintain product quality and protect equipment.

In addition to its outstanding heat resistance, our High Silica Fiberglass Fabric Filter also exhibits excellent chemical resistance, ensuring durability and reliability even in corrosive environments. This makes it an ideal choice for industries that require filtration in the presence of aggressive chemicals.

Parameter

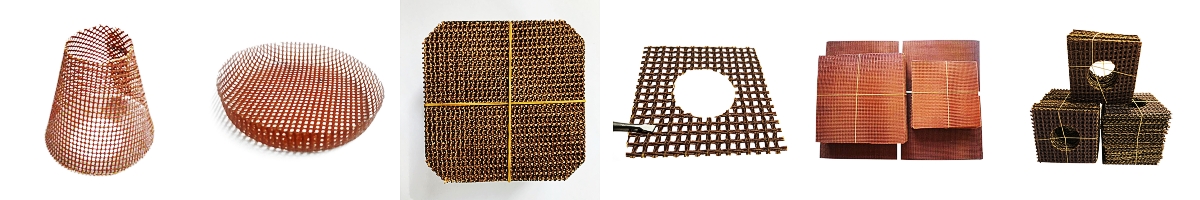

High Silica Fiberglass Fabric Filter for Steel Iron is a remarkable solution designed specifically for high-temperature applications. Crafted with precision using high-quality materials, this product excels in heat resistance, making it the ideal choice for industries that require a reliable and durable filtration solution.

Cangchen High Silica Fiberglass Fabric Filter is manufactured from high silica glass fiber, a material known for its exceptional resistance to extreme heat. This specialized fabric is capable of withstanding temperatures well beyond the limits of traditional filter materials. It is specifically engineered to provide long-lasting performance in environments where high temperatures and thermal fluctuations are prevalent.

In casting production, the rejection rate of castings is 50 to 60% due to casting problems such as non-metallic inclusions. The inclusions do not only reduce mechanical properties of the casting, but also has a great influence on processability and appearance. For the purification of liquid casting alloys, reducing or filtering various non-metallic inclusions is an important technical measure to obtain good quality castings, and the use of casting filters has become an important auxiliary material for purification of liquid casting alloys.

| Type | High Silica Fiberglass Filter Mesh For Steel Iron And Copper | |

| Work Temperature | ≤1620℃ | |

| Softening Temperature | 1700℃ | |

| Continuous Working Hours | <10 Min.(1400-1450℃) | |

| <4 Min.(1450-1560℃) | ||

| <15 Seconds.(1560-1620℃) | ||

| Gas Emit | ≤60cm 3/g | |

| Thickness | 1.5mm | |

| Weight | 520-580 g/m2 | |

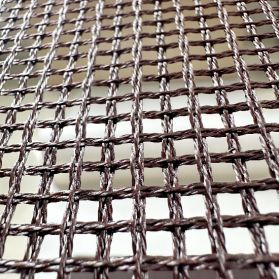

| Weave Pattern | Mock Leno | |

| Hole Size | 1.5*1.5/2.0*2.0/2.5*2.5mm | |

| Mesh Opening Chosen | White Iron | 1.5mm |

| Gray Iron(Pour weight≤100kgs ) | 1.5mm | |

| Gray Iron(Pour weight≥100kgs ) | 2.0mm | |

| Malleable Iron | 1.5mm | |

| Compacted Graphite Iron | 1.5mm & 2.0mm | |

| Ductile Iron(Pour weight ≤ 100kg) | 2.0mm | |

| Ductile Iron(Pour weight ≥ 100kg) | 2.5mm | |

| Carbon Steel | 1.5mm | |

| Stainless Steel | 1.5mm | |

| Brass | 1.5mm & 2.0mm | |

| Bronze | 1.5mm & 2.0mm | |

| Certificate | MSDS | |

| ISO9001:2015 | ||

The high silica fabrics used in this product are carefully woven to create a robust and resilient fabric structure. This ensures that Cangchen High Silica Fiberglass Fabric Filter can withstand the demanding conditions commonly found in steel and iron manufacturing processes. Its high-temperature heat resistant fabric properties ensure reliable filtration even in the harshest operating environments.

The use of silica fiber cloth in our fabric filter further enhances its heat resistance capabilities. Silica fiber cloth offers excellent thermal insulation, protecting the fabric from damage and ensuring prolonged performance under extreme conditions. Its exceptional resistance to heat, flames, and molten metal splashes makes it a critical component of our High Silica Fiberglass Fabric Filter.

● Cost effective and easy to use, easy fit existing pattern equipment

● Eliminates inclusions created by ceramic chips

● Improves metal fluidity and distribution, reduce turbulence

● Removes micron sized inclusions and impurities

● Minimize gating system to reduce cost

● No need for pre‐Heat, non‐chilling

● Unique function as riser or gating parts knock‐off removal

1. Use area of filter net: F1 = F2 / AxB

● F1: the cross-sectional area of the casting system.

● F2: the original cross-sectional area of the casting system.

● A: the porosity of the filter screen, generally 50-60%.

● B: the filtration rate of filter screen, generally 60-80%.

Therefore, the cross-sectional area of the casting system is generally 2-4 times that of the casting system without the casting net.

2. Position of filter screen:

● Place the filter under the sprue cup;

● Placed on the parting surface under the sprue;

● Three different positions on the lap surface of the runner.

Choose Cangchen High Silica Fiberglass Fabric Filter for Steel Iron and experience the unmatched performance and longevity it offers. Our high silica fiberglass fabric filter sets the standard for high-temperature filtration solutions, providing peace of mind and exceptional results in demanding industrial applications. Contact us today to discuss your specific filtration needs and let our team of experts assist you in finding the perfect solution for your requirements.

The foundry industry generally uses stainless steel mesh, fiber filter mesh, straight hole filter mesh, foam ceramic filter mesh, etc. to purify molten metal. Fiberglass filter has become a more commonly used casting auxiliary material due to its low cost, simple production and convenient use.

According to the different materials used, it can be divided into alkali-free mesh, medium-alkali mesh, high-silica mesh and other filters.

One for cast aluminum is generally made of alkali-free mesh, for cast iron and steel is generally made of high-silica glass fiber mesh.

| Mesh Material | Features | Applications |

| Stainless Steel | Durable and long-lasting | Excellent heat and corrosion resistance | High mechanical strength | Fine mesh for precise filtration | Purification of molten metal | Investment casting | High-temperature applications | Non-ferrous metal casting |

| Fiber Filter | Low cost and simple production | Convenient to use | Good thermal stability | Suitable for large-scale production | Purification of molten metal | Gravity and low-pressure casting | Removal of slag and impurities |

| Straight Hole Filter | Precise filtration with uniform hole size | Effective removal of impurities | High mechanical strength | Excellent thermal stability | Purification of molten metal | Non-ferrous metal casting | High-temperature applications | Steel and iron casting |

| Foam Ceramic Filter | Excellent thermal stability and resistance to thermal shock | High porosity for efficient filtration | Even distribution of molten metal | Purification of molten metal | Aluminum and iron casting | Investment casting |

| Fiberglass | Low cost and simple production | Convenient to use | Good chemical resistance | High mechanical strength | Purification of molten metal | Gravity and low-pressure casting | Non-ferrous metal and alloy casting |

| Alkali-Free Mesh | Suitable for cast aluminum | Efficient purification | Good thermal stability | Filtration in aluminum casting | Removal of oxides and inclusions |

| Medium-Alkali Mesh | Suitable for various metal alloys | Reliable filtration efficiency | Excellent resistance to molten metal | General-purpose filtration | Steel, iron, and non-ferrous casting | High-temperature applications |

| High-Silica Mesh | Ideal for cast iron and steel | Withstands high temperatures and corrosive environments | High mechanical strength | Excellent thermal stability | Filtration in iron and steel casting | Removal of impurities and inclusions | High-temperature applications |

1.What is high silica fiberglass filter mesh?

High silica fiberglass filter mesh is a high temperature resistant inorganic fiber material. It removes impurities from molten metal. If you need to do small castings, choosing a high-silica glass fiber filter can fully meet your needs.

2.Can high silica fiberglass filter mesh withstand high temperatures?

The high-silica glass fiber filter can work continuously at a temperature of 1000 °C and short-term temperature resistance of 1400 °C. It is an excellent inorganic material with high-temperature resistance, heat insulation, and heat preservation.

3.How is high silica fiberglass filter mesh made?

The high silica glass fiber filter mesh is a filter mesh woven with high-silica glass fiber. The surface of the high silica glass fiber filter mesh is coated with a high-temperature resistant coating. Finally, a filter mesh with a certain rigidity is produced.

4.How to use high silica fiberglass filter mesh?

The high silica fiberglass filter mesh can be used to filter and purify impurities in metal smelting and casting.

If you are interested in the Fiberglass Filter For Steel, welcome to contact us.

Application:

Filtration of Molten Steel

Ductile Iron

Gray Iron

Compacted Graphite Iron

Copper and Aluminium

Silica Mesh Filter For Foundry Casting Metal Filtration

Silica Mesh Filter For Molten Aluminium, Steel, Iron and Copper Filtration.

Fiberglass Mesh Filter For Molten Metal Casting

High Temperature Carbonized Fiberglass Mesh Filter For Foundry Filtration

High Silica Fiberglass Fabric Filter Mesh For Steel Iron And Copper (Thick Type)

High Silica Fiberglass Fabric Filter Mesh For Steel Iron And Copper (Thick Type)

Smokeless Odorless Fiberglass Casting Filter Mesh For Aluminum

Smokeless Odorless and Flameless Fiberglass Casting Filter Mesh For Aluminum liquid Filtration.

TF Combo Bag For Aluminum Ingot And Slab Filtration

Look forward to hearing from you:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation