The cap-style fiberglass filter mesh is woven with special high-twist & high-strength alkali-free fiberglass yarn, coated with phenolic resin and special post-treatment. The maximum temperature resistance can reach 900 ℃.

For some castings that require high surface quality and good densification, in order to prevent inclusions and improve the internal quality of the castings, it is very necessary to install a cap type fiberglass filter mesh in the gate system. Especially in the field of small and medium-sized castings, such as automobiles, high-speed railways, machine tools and hydraulic parts.

Cap Filter Mesh can effectively reduce more than half of the slag, impurities caused by the waste phenomenon. This is also the main reason for the wide use of filters, is also the main trend.

The cap filter mesh is a process method to simplify the casting process difficulty. It reduces the cost and improves the qualified rate of the product. Its application is wide. It is an ideal filter material for various metal melts.

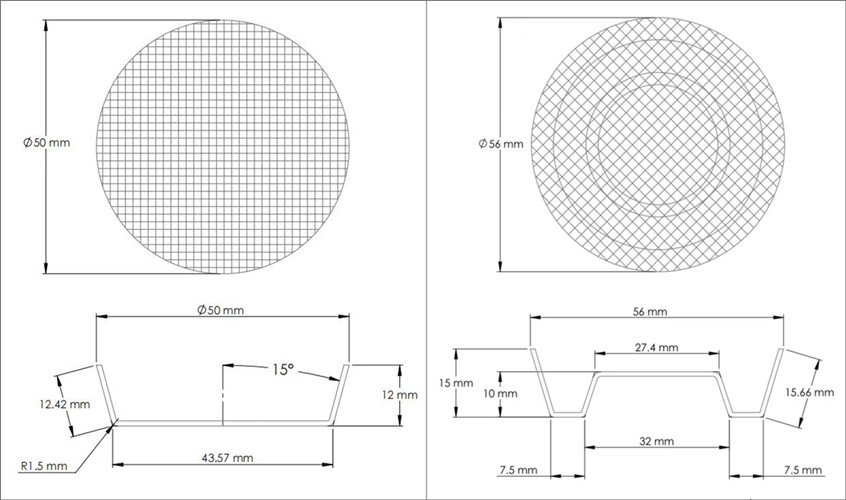

Parameter

Cap Filter Mesh, also known as Mesh filter cap, are widely used in all walks of life and are commonly used as components in the filtration process. It is widely used in automobile and motorcycle wheels, cylinder pistons, aluminum rods, aluminum materials, aluminum ingots, aluminum plates and precision casting of all types of aluminum alloy casting.The structure of the covered mesh cap is simple, economical and practical, and the data such as filtration accuracy, size, appearance and shape can be adjusted as needed.

Cap type fiberglass filter mesh is usually a network structure, which is a non-metallic liquid metal purification device with the required mesh opening. Its porosity is higher, the slag collection surface area is larger, and it can reduce the the Reynolds number of the mesh metal surface flowing through the cast filter, then it can make the filler be more stable and reduce the production of secondary oxidation slag in the mold.

Cangchen can provide you with customized services and recommendations according to your needs. If you need Cap Filter Mesh, just click the button below.

Hot press set shape & Side cut trimming

Cap Filter Mesh Features and Functions:

● Carbonized by High Temperature.

● Coated with special resin.

● Smokeless & Odorless & Flameless.

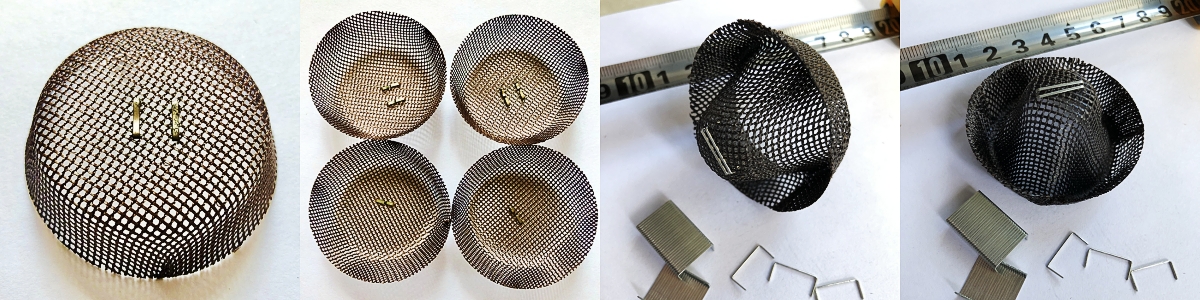

● With one or two staple or not, up to clients' need.

● Effectively remove impurities, reduce turbulence and eliminate air bubbles from molten aluminium.

● Improving the quality of castings and reducing costs.

● The aluminium filtered by this mesh can be recycled again.

● It is environment-friendly products.

● All shapes can be customized according to clients' requirements.

The usage of cap type fiberglass filter mesh can effectively remove liquid metal and non-metallic inclusions, improve the structure and mechanical properties of castings, improve the high quality standards of precision castings production and reduce the rate of casting defects. It can also reduce tool wear during machining and significantly improve efficiency. In addition, it can reduce porosity in the casting, reduce surface defects and reduce casting and filling lines, significantly increasing the process yield, which is much better than high silicon screen casting filters and cast filter products with straight holes.

Purification mechanism of cap type fiberglass filter mesh:

1. Since the cap fiberglass filter mesh is placed at the bottom of the gate of the sprue cup, runner or sand mold, the molten metal injected from the sprue cup into the cavity can stay momentarily while passing through the position. The slag can be the main small-density inclusions floating and separating from the molten metal. These inclusions also produce deep adsorption when they pass through regular or irregular grids. This phenomenon can continue to purify molten metal before the pouring cup is filled.

2. The role of surface filtration: Surface filtration is a common metal liquid purification function of all casting filters. When the molten metal passes through the casting filter, unfloated or floating inclusions with a relatively large surface area, such as molten slag, are captured by the surface of the casting filter. In addition, the captured inclusions will form a finer filter eye with the cast filter continue trapping subsequent inclusions, thus enhancing the filtration effect. However, at the same time of this surface filtration, with the decrease of the pouring temperature and the increase of the viscosity of the molten metal, as well as the extension of the pouring time, the cap filter mesh will be blocked to varying degrees, thus make filtering effect be worse.

So, the cap filter mesh should be replaced with a new one according to actual casting scenario to keep its best filtering effect.

To use the fiberglass mesh filter to replace the traditional wire mesh filter and realize fiberglass aluminium filtration:

● Never change molten aluminum element or contaminate molten aluminum.

● No worry about the riser remelt anymore and easy to handle the aluminum scrap recycling.

● Fiberglass mesh can float on top of molten aluminum in furnace being remelt and recycled and it can be more easily scooped out.

● Reduces molten aluminum turbulence and improves distribution and flow.

● Remove oxides and inclusions to improve castings mechanical properties and surface finish.

● Excellent stiffness and toughness, good heat resistance.

The cap fiberglass filter mesh cost is cheap, easy to use, it can improve the mechanical properties of castings without changing the metal composition, improve the production quality of castings. At the same time, it is resistant to high temperature and ablative properties, and it can operate at temperatures of about 850 degrees.

1. Improve the graphite form in the casting to reduce the graphite size, thinner thickness and slightly curved shape.

2. Change the machining performance of castings and improve the processing speed.

3. Stabilize the metal melt and flow rate, completely protect the cavity and prevent the metal melt from damaging the cavity and causing sand clamping defects in the casting!

4. Prevent the flow of metal melt too fast, resulting in sand expansion, cavity drop, burrs and uneven surface!

5. Eliminate bubbles to increase the density and hardness of the casting and the tensile strength at room temperature.

6. Efficient removal of impurities, reduce casting inclusions, air, slag holes and trachoma defects, greatly reducing the defective rate!

7. The trial production range includes cast steel, cast iron, cast copper, cast aluminum, sand casting, bright casting, wax casting and lost casting, water glass and resin sand casting, which greatly improve the production of castings and reduce foundry costs.

Materials: Fiberglass

Shapes: The shapes of filter screen products are: rectangle, square, circle, ellipse, ring, rectangle, hat, waist, and special-shaped.

Types: single-layer, double-layer, and multi-layer.

Produce process: The different shapes of the filter mesh, and the technology is also different.

| Type | Fiberglass Cap Filter For Aluminum |

| Work Temperature | 700-800℃ |

| Softening Temperature | 900℃ |

| Continuous Working Hours | <20Min.(700-800℃) |

| SiO2 | 58%-65% |

| Loss on ignition | ≤3% |

| Gas Emit | ≤30cm3/g |

| Thickness | 0.35-0.5mm |

| Weight | 150-350 g/m2 |

| Hole Size | 0.8*0.8/1.0*1.0/1.2*1.2/1.5*1.5/2.0*2.0/2.5*2.5mm |

| Weave Pattern | Leno |

| Certificate | SDS |

| ISO9001:2015 |

Cangchen is a professional foundry filtration products manufacturer who focuses on production, sales, service and solutions. If you want to know more about our Cap Filter Mesh price, we are online 24 hours a day and welcome your consultation.

1.How is the cap filter mesh made?

The cap filter mesh is made of high-silica fiber mesh cloth and frosted mesh cloth as the basic material. It is a mesh with a certain degree of rigidity made by coating the surface with high temperature-resistant paint. The fiber filter for cast aluminum is generally made of alkali-free mesh. Fiber filters for cast iron and cast steel are generally made of high-silica glass fiber mesh.

2.How to use a cap filter mesh?

Cap filter is often used to form cavities for castings that are complex or difficult to form. It can be used for investment casting. You can use it for automobiles, motorcycle wheels, cylinders, pistons, aluminum rods, aluminum materials, aluminum ingots, aluminum plates, and various aluminum alloy parts. In addition to being an ideal filter material for various metal melts, it can also be used for the filtration of chemical corrosive liquids and high-temperature gases.

3.What are the advantages of the cap filter mesh?

The cap filter mesh can effectively remove harmful impurities in the metal melt and improve the casting mechanical properties. It can improve the graphite morphology in the casting and change the casting machinability.

4.What are the types of casting filters mesh?

The casting filters types include molten aluminum filters, molten iron filters, molten steel filters, etc. According to materials, it can be divided into special fiber filters for casting, ceramic foam casting filters, and honeycomb ceramic casting filters.

5.What are the types of fiber filters for casting?

Fiber filters for casting can be divided into fiber filters for molten steel, molten iron, and molten aluminum according to the use. According to different shapes, it is divided into flake, round, spherical, cap, cylindrical filter and so on. According to different materials, it can be divided into the alkali-free mesh, medium-alkali mesh, high-silica mesh, and other filters.

6.Can the cap filter mesh withstand high temperatures?

Different materials have different temperature resistance. The cap filter mesh can generally withstand instantaneous high temperatures of more than 1000 degrees.

7.What is the mesh size of the cap filter mesh?

It can be divided into 0.8mm, 1.0mm, 1.5mm, 2.0mm, and 2.5mm according to the mesh size.

8.Can the cap filter be cut?

The mesh can be cut into any size shape with scissors. You can place it under the pouring cup, on the overlapping surface of the runner, the runner and the sprue overlap surface, and press the box tightly.

Application:

1. The filter screen can effectively remove the physical impurities in the collection and filtration system.

2. Protect the pipeline equipment, and improve the performance of the filter medium.

3. It is suitable for various fuel filters, liquid filtration, and water treatment equipment.

4. Filter mesh is used in mechanical air ventilation,it can maintain the mechanical cleaning and prevent sundries from into the cavity.

5. Filter through the screen, so as to avoid sundries, in order to increase the service life of the machine.

6. Filter mesh is suitable for distillation, absorption, evaporation and filtration in petroleum, oil refining, chemical, light industry, medicine, metallurgy, machinery and other industries.For example,Filtration of molten aluminium.

Silica Mesh Filter For Foundry Casting Metal Filtration

Silica Mesh Filter For Molten Aluminium, Steel, Iron and Copper Filtration.

Smokeless Odorless Fiberglass Casting Filter Mesh For Aluminum

Smokeless Odorless and Flameless Fiberglass Casting Filter Mesh For Aluminum liquid Filtration.

TF Combo Bag For Aluminum Ingot And Slab Filtration

Look forward to hearing from you:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation