Sep. 02, 2025

Recently, there are always customers who are focusing on foundry filtration asking this question.

So, here let's see what are basic differences between metal wire mesh filter and fiberglass filter mesh.

Firstly, traditional Galvanized steel or iron wire mesh filters are commonly used for low pressure castings filtration, especially for aluminum alloy wheels.

● What the greatest advantage is: Wire mesh filters are cost effective, with good strength and flexible on shapes and sizes.

● But the fatal defect is: there will be largely Fe element added to the aluminum castings when using wire mesh filter, which will be lower castings mechanical strength, especially for high quality standard, this is not acceptable.

● Aluminum will be polluted after filtration by metal filters, meanwhile aluminum liquid with metal filters can NOT be recycled to filter again.

● For risers containing wire mesh filters after solidification, it can not remelted directly to furnace, even after the treatment. The direct cost is the risers had to be sold as scrap.

● This will cost huge waste no matter material or cost.

Fortunately, now there is a new and better material to perfectly replace metal wire filter mesh.

● Fiberglass filter mesh are specially designed and woven for diffusion and filtration of molten aluminum.

● High twisted yarns are used to control strand diameters and resist fattening or distortion under pressure from contact with molten metal.

● The integrity of the weave pattern is maintained by coating phenolic resin and by leno or plain construction in high density.

● Regular coating and carbonized treatment are both available for filtration of aluminum liquid.

● Widely used in automobile and motorcycle wheels, cylinder pistons, aluminum rods, aluminum materials, aluminum ingots, aluminum plates and precision casting of all types of aluminum alloy casting.

● The most important thing is: Fiberglass filter mesh does not pollute the aluminum liquid and does not affect the chemical properties of the metal.

● The biggest difference is: aluminum waste containing fiberglass filter mesh, as well as aluminum liquid from sprue and the riser can be directly returned to the furnace for remelting, greatly reducing costs and save material.

Hebei CangChen has been already devoted to research and development such fiberglass filter mesh for many years, and our filters have been tested by many clients from the world, and all is passed.

Our filters have been servred many foundry factories with best quality and perfect after sales service.

1. Filter cloth in roll (white & brown, without/with coating):

It can be fixed in the aluminum liquid flow tank, used for aluminum ingot, aluminum rod, aluminum strip and other continuous casting workshop to purify aluminum liquid.

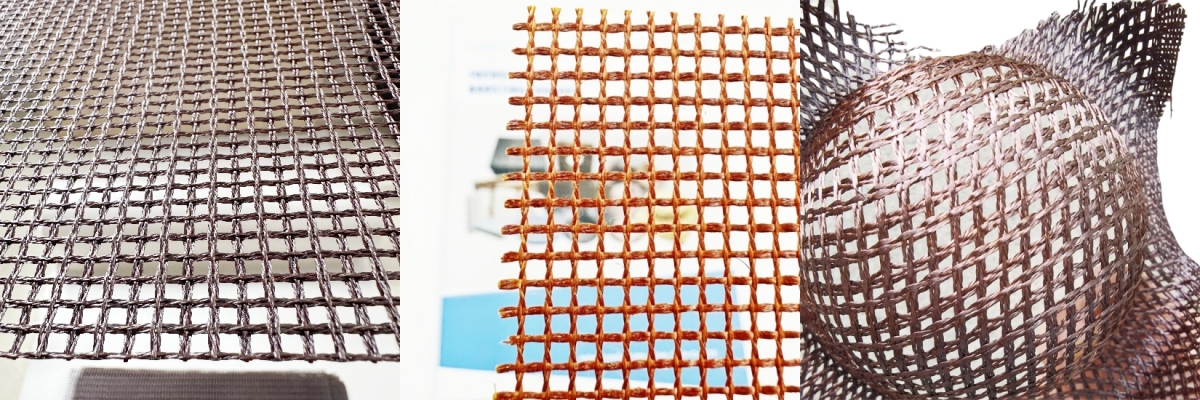

2. Cutting mesh (brown, coated with resin):

Square, round, fan and other heteroideus mesh cutted just according to client's requirements. Used for filtering aluminum castings and placed in the gating system.

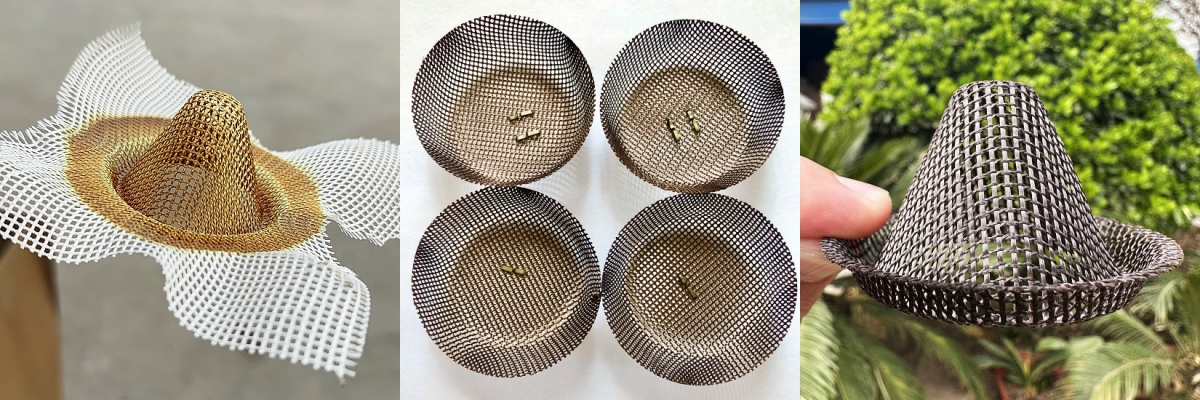

3. Cylinder, cap and other special shapes (brown or black, coated with resin or carbonized):

Used for low pressure casting, such as aluminum alloy wheels, engine cylinder head and so on.

4. Smokeless filters (black carbonization treatment):

No combustion, smokeless, low gas output during the filtration process, for high quality requirements of casting production, such as aluminum alloy piston.

5. High silica fiberglass filter mesh:

Weaved by high silica fiberglass yarn and coated with special refractory coating.

Ideal for in-mold filtration of gray, malleable, white, compacted graphite and ductile cast irons, as well as non-ferrous aluminum and copper-based metal alloys and many types of small scale steel casting filtration.

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation