Sep. 04, 2025

Alumina Ceramic Foam Filter Plate is mainly used in smelting filtration of aluminum and aluminum alloys.

It can efficiently filter residues such as oxide slag, oxide scale, non-metallic inclusions and gate groove linings in molten aluminum, and solve the problem of aluminum and aluminum alloys being sensitive to internal defects.

The unique production process and detection method make the alumina filter plate with high opening rate, uniform pore structure and high surface strength.

Available in 7" to 26", mesh up to 60ppi filter plates.

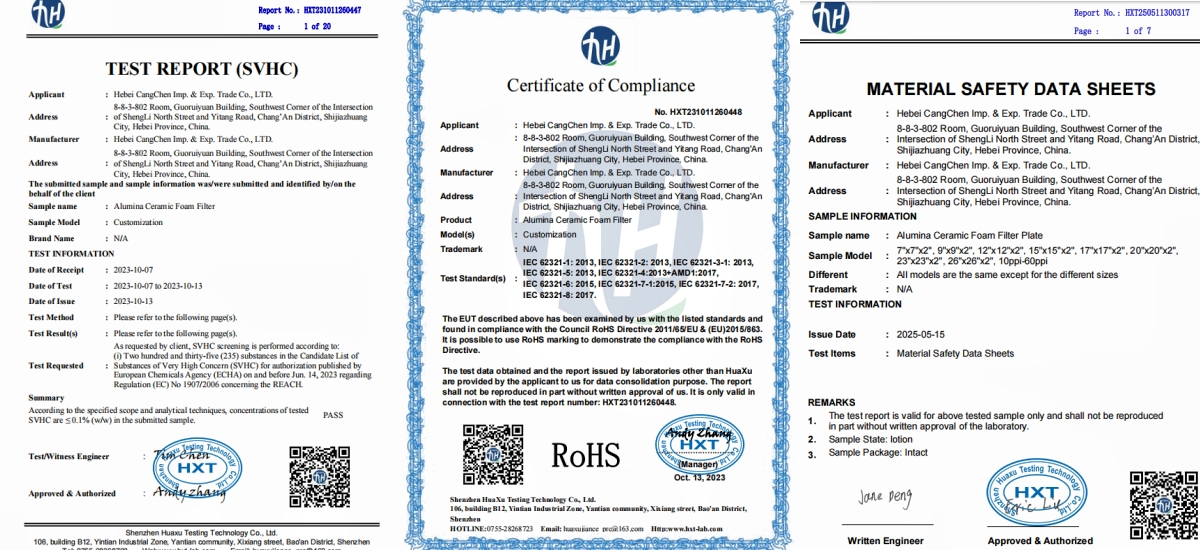

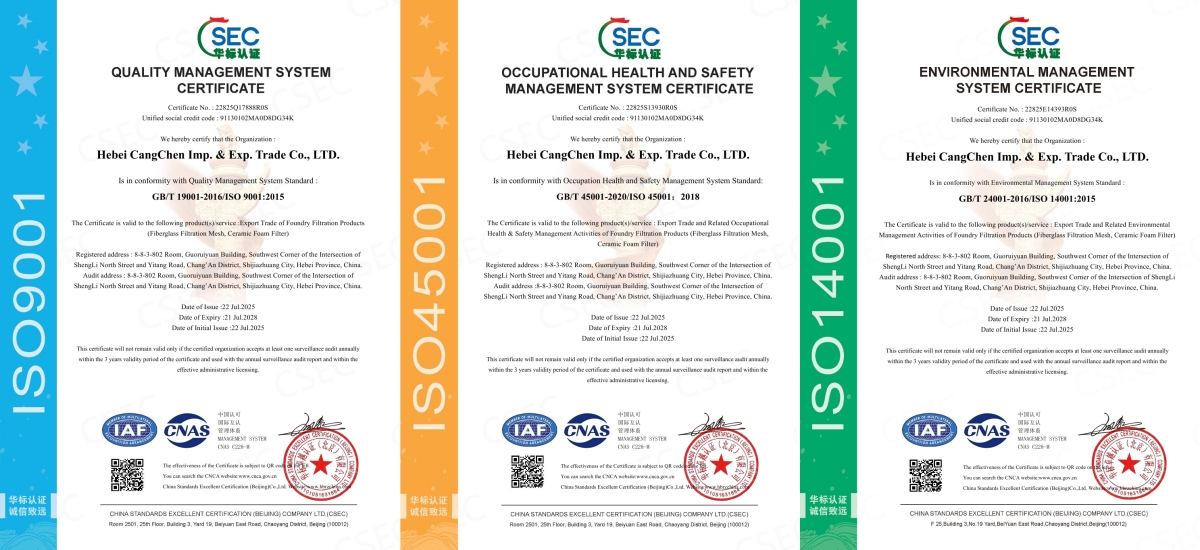

Our Alumina ceramic foam filters have exported to many countries already because of its outstanding quality and the favorable reputation among customers with REACH & RoHS and MSDS certifications.

We, Hebei CangChen, who are focusing on these filters for many years. We have customized many different shapes and ppi for our each client according to their own requirements.

Our company has obtained ISO 9001, ISO45001 and ISO14001 certifications.

1. Clean filter box

2. Gently put the filter plate into the filter box, and press the sealing gasket around the filter plate by hand to prevent the flow of molten aluminum.

3. Evenly preheat the filter box and filter plate to make it close to the temperature of the molten aluminum. Preheat to remove moisture and facilitate initial instant filtration. Preheating can be carried out using electric or gas heating. Under normal circumstances, it takes about 15--30 minutes.

4. Pay attention to the change of the aluminum hydraulic head during casting. The normal initial pressure head is 100-150mm. When the molten aluminum begins to pass, the pressure head will drop below 75--100mm, and then the pressure head will gradually increase.

5. During the normal filtration process, avoid knocking and vibrating the filter plate. At the same time, the launder should be filled with molten aluminum to avoid too much disturbance of the aluminum liquid.

6. After filtration, take out the filter plate in time and clean the filter box.

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation