Sep. 19, 2025

1. The use of filters can improve the mechanical properties of the castings, increase the hardness of the castings, make the surface hardness uniform and improve the bending strength of the castings.

● Change the graphite morphology of the casting, so that the graphite size is reduced, the thickness is thinner, and the shape is slightly curved.

● Change the machining performance of castings and improve the processing efficiency.

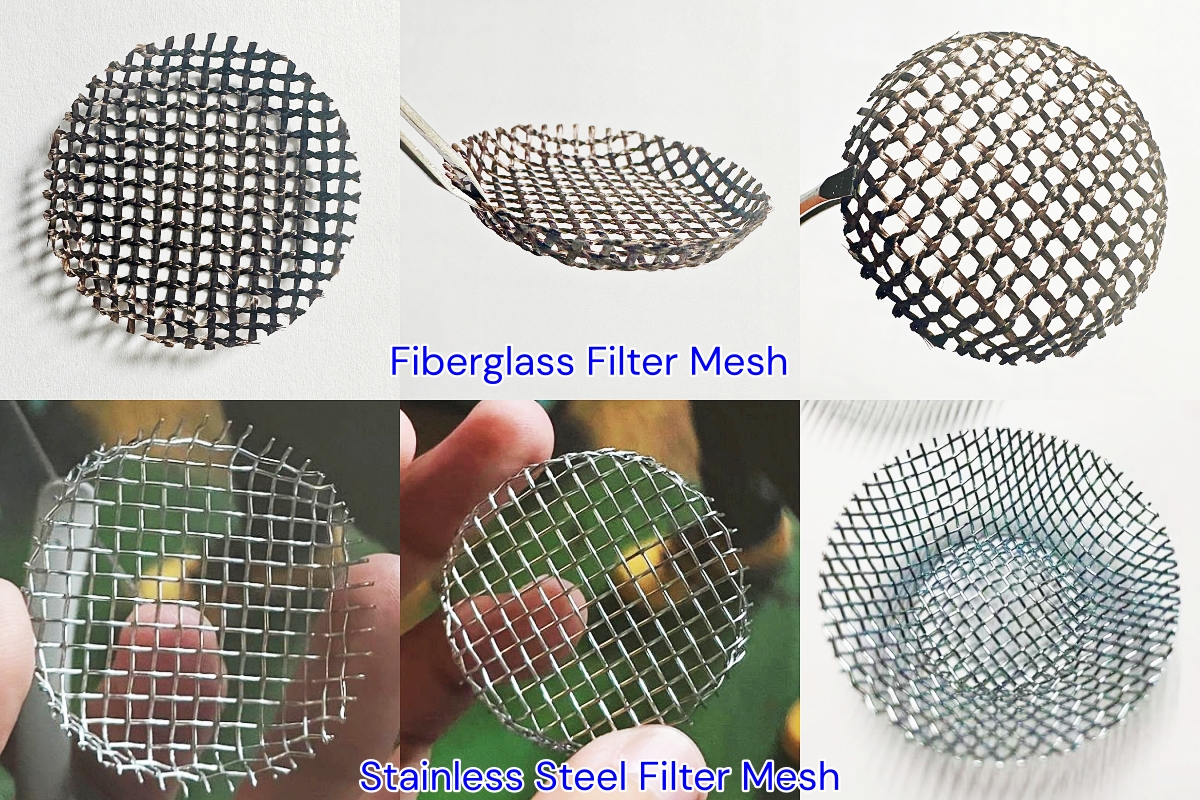

Main varieties of fiberglass filter mesh are: molten aluminum, iron, steel, copper filter, casting filter, etc.

2. Change the machining performance of castings and improve the processing efficiency.

● Compared with all various filters, the high temperature resistant fiberglass filter mesh does not affect the composition of aluminum alloy.

● The filtration effect is better because the fiber itself has the effect of absorbing impurities.

Because the casting filter mesh has the advantages of high temperature resistance, good mesh stability, convenient use, etc., it is also conducive to the recycling of molten metal waste ( the mesh is floated on the surface of the aluminum solution after the waste is returned to the furnace). High temperature resistant fiberglass filter cloth is an ideal filter material for high-grade aluminum alloy castings.

3. It not only has good properties, such as: high temperature resistance, ablation resistance and chemical stability, but also has good steel strength and resistance to metal melt erosion.

In casting production, there are some quality problems of slag holes, sand holes, and gas holes for steel castings, iron castings, aluminum castings and other alloy castings due to various reasons.

Therefore, there are great technical value and economic value for improving casting yield and quality that the non-metallic inclusions in the metal melt are removed.

At present, a large number of manufacturers use metallic barbed wire as a filter material, but due to the presence of a large amount of iron (Fe) elements, the blanks waste parts containing the filter, gate and riser can only be treated as waste aluminum.

But aluminum liquid filtered by Fiberglass filter mesh can be directly returned to the furnace for remelting, which greatly improves the reuse rate of waste aluminum and reduces the cost.

| Material | Features | Reaction with liquid | Fe Element | Contaminate liquid | Filter recycle | Liquid recycle and re-filter |

| Fiberglass yarn | Soft | No | No | No | Yes | Yes |

| Metal wire mesh | Hard | Yes | Yes | Yes | No | No |

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation