Sep. 19, 2023

A Silica Fiberglass Filtration Filter is an essential component in various steel production processes, particularly in the casting and pouring stages. These filters are designed to remove impurities and solid particles from molten steel, ensuring that the final product meets quality standards. In this comprehensive guide, we will explore the use, benefits, and best practices for Silica Fiberglass Filtration Filters in steel manufacturing.

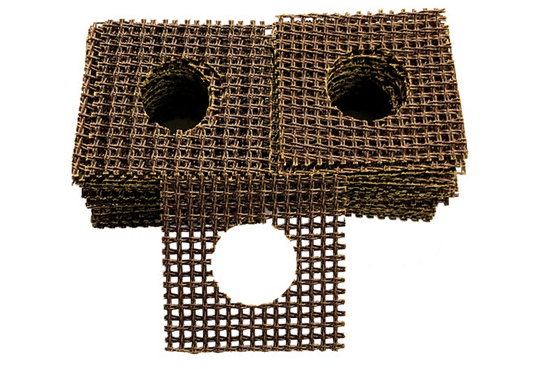

Silica Fiberglass Filtration Filters are typically made of high-purity silica fiberglass material with a unique structure that allows them to effectively trap and remove impurities from molten steel. They are available in various shapes and sizes to suit different applications and can be used in both ladle and tundish filtration systems.

Using Silica Fiberglass Filtration Filters in steel manufacturing offers several advantages:

- Improved Steel Quality: Filtration filters effectively remove non-metallic inclusions, slag, and other impurities from molten steel, resulting in a higher-quality end product with fewer defects.

- Enhanced Casting Performance: Clean steel reduces nozzle clogging and improves the flow characteristics during casting, reducing downtime and increasing productivity.

- Consistent Mechanical Properties: Filtration helps maintain consistent mechanical properties of the steel, ensuring that it meets specified standards and performance criteria.

- Reduced Rework and Scrap: By preventing inclusions and defects, filtration reduces the need for costly rework or scrapping of steel batches.

- Extended Equipment Life: Filtration also protects downstream equipment such as molds and casting nozzles, prolonging their lifespan and reducing maintenance costs.

Silica Fiberglass Filtration Filters for Steel

Here is a step-by-step guide on how to use Silica Fiberglass Filtration Filters effectively in steel manufacturing:

1. Determine Filtration Requirements: Identify the specific impurities or inclusions you need to remove from your molten steel. Different filtration filters are designed for specific applications, so choose the appropriate type.

2. Select Filter Size: Consider the size of your ladle or tundish and the flow rate of molten steel to select the right filter size. Proper sizing ensures efficient filtration without causing excessive pressure drop.

3. Evaluate Filtration Efficiency: Assess the filtration efficiency of the filters you plan to use. High-efficiency filters can capture smaller particles and provide better results.

1. Cleanliness: Ensure that all equipment, ladles, and tundishes are clean and free from contaminants before introducing the filter.

2. Proper Placement: Position the filter correctly in the ladle or tundish to intercept the flow of molten steel. Secure the filter in place to prevent movement during the casting process.

3. Heating: Preheat the filtration filter to the appropriate temperature before use to prevent thermal shock and ensure efficient operation.

1. Flow Control: Maintain a steady and controlled flow of molten steel to prevent turbulence that can dislodge or damage the filter.

2. Monitoring: Continuously monitor the filtration process to ensure that the filter is functioning correctly. Watch for any signs of clogging or reduced filtration efficiency.

3. Replace as Needed: Depending on the application and the condition of the filter, replace it when it reaches its maximum capacity for impurity removal.

1. Quality Inspection: After the steel has passed through the filtration filter, conduct quality inspections to verify that impurities have been effectively removed.

2. Documentation: Maintain detailed records of filtration processes, including filter types, sizes, temperatures, and results, for quality control and future reference.

3. Maintenance: Regularly inspect and clean the filtration system components to ensure their longevity and continued performance.

Safety is paramount when using Silica Fiberglass Filtration Filters mesh in steel manufacturing. Some safety considerations include:

- Personal Protective Equipment (PPE): Ensure that operators and workers wear appropriate PPE, including heat-resistant clothing, gloves, and safety glasses.

- Handling Precautions: Handle the filters with care, especially when they are preheated. Use appropriate equipment and follow safety protocols to prevent accidents.

- Ventilation: Ensure proper ventilation in the casting area to mitigate exposure to fumes and gases produced during the steelmaking process.

- Training: Provide comprehensive training to operators and workers regarding the safe use of filtration filters, including handling, maintenance, and emergency procedures.

Proper maintenance and storage of Silica Fiberglass Fabric Filter are crucial for their longevity and effectiveness:

- Store filters in a clean and dry environment to prevent contamination and degradation.

- Regularly inspect filters for signs of wear, damage, or deterioration, and replace them as needed.

- Follow manufacturer recommendations for filter maintenance and storage to ensure optimal performance.

Select a reliable and reputable supplier for your Silica Fiberglass Filtration Filters. Ensure that the filters meet industry standards and undergo quality testing. Regularly assess the performance of filters and maintain open communication with your supplier for ongoing quality assurance.

In summary, Silica Fiberglass Filtration Filters are indispensable tools for improving the quality and performance of steel production processes. Proper selection, handling, and maintenance of these filters are critical to achieving optimal results. By following the guidelines outlined in this guide and prioritizing safety and quality, steel manufacturers can ensure the successful use of Silica Fiberglass Filtration Filters in their operations.

Hebei Cangchen is a professional foundry filtration products manufacturer who focuses on production, sales, service and solutions. We are the recognized leader in the development and production of casting filters at home and abroad and possess excellent innovation capabiities in filter manufacturing technology.

If you want to know more information about Silica Fiberglass Filtration Filters, please click on the image below to get a free quote:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation