Aug. 18, 2025

More and more clients who are working for foundry factories from all over the world are attracked by our fiberglass cap filters.

1. How are the fiberglass cap filters produced by Hebei CangChen one step by one step?

2. What are the advantages/difference between such cap filters and metal type?

3. How can we order the appropriate size?

Let's talk one by one!

Firstly, Correct fiberglass filter cloth are chosen is the first step!

Different filtration requirements will use the different mesh opening of fiberglass filter cloth. We need to weave the cloth accorrding to clients request.

Secondly, Coating special phenolic resin on the cloth.

Special phenolic resin are coated on the cloth, which will make the cloth harder, finalize the design and strengthen the mesh.

Thirdly, Cutting suitable cloth into small pieces.

Due to different dimensions of cap filters, so, different pieces are cut to be standby.

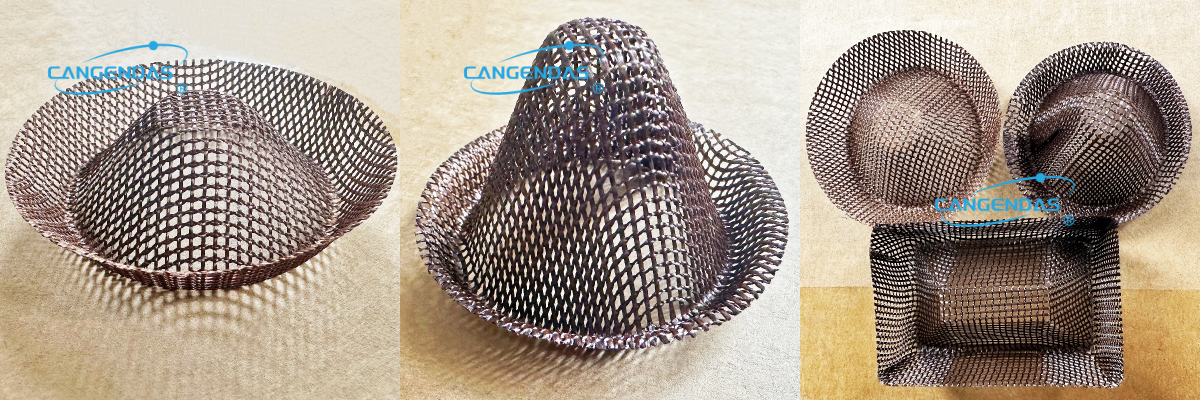

Fourthly, Make the required shape by moulds and Cut extra edges.

The small pieces cut from the third step are shaped by different moulds to produce each shape, and also, the extra edges are cut down to make sure the outside precise dimensions.

Make the cap shape & Cut extra edges

Fively, Carbonized at a certain temperature.

This is very important process for this filters. Temperature and carbonization time must be controlled very well to keep cap filter not warpage and not soft.

Advantages/difference from metal type:

● Fiberglass cap filter is usually a network structure, which is a non-metallic liquid metal purification device with the required mesh opening.

● Its porosity is higher, the slag collection surface area is larger, and it can reduce the the Reynolds number of the mesh metal surface flowing through the cast filter, then it can make the filler be more stable and reduce the production of secondary oxidation slag in the mold.

● The usage of cap type fiberglass filter mesh can effectively remove liquid metal and non-metallic inclusions, improve the structure and mechanical properties of castings, improve the high quality standards of precision castings production and reduce the rate of casting defects.

● It can also reduce tool wear during machining and significantly improve efficiency.

● In addition, it can reduce porosity in the casting, reduce surface defects and reduce casting and filling lines, significantly increasing the process yield, which is much better than high silicon screen casting filters and cast filter products with straight holes.

● For some castings that require high surface quality and good densification, in order to prevent inclusions and improve the internal quality of the castings, it is very necessary to install a cap type fiberglass filter mesh in the gate system.

● Especially in the field of small and medium-sized castings, such as: automobiles, high-speed railways, machine tools and hydraulic parts, the purification effect of the cap filter mesh has been widely recognized by most foundry workers.

There are two ways to produce your order with exact dimensions as follow:

1. The best way is to send us your filter drawing, then we will make the mould accordingly and produce samples for you to test, if available, then you can place big order to us.

2. You can also send us your filters that you are using at present, no matter what material, we will measure the dimensions. Then make the same samples for your test.

Please leave us a message, we will reply you as soon as possible!

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation