Oct. 23, 2025

Fiberglass Filtration Cloth is woven with special high-twist & high-strength alkali-free fiberglass yarn!

"Smokeless & Odorless & Flameless" Fiberglass filter mesh is coated with special resin, carbonized by high temperature and special post-treatment.

● Filter cloth in roll (white & brown, without/with coating) : It can be fixed in the aluminum liquid flow tank, used for aluminum ingot, aluminum rod, aluminum strip and other continuous casting workshop to purify aluminum liquid.

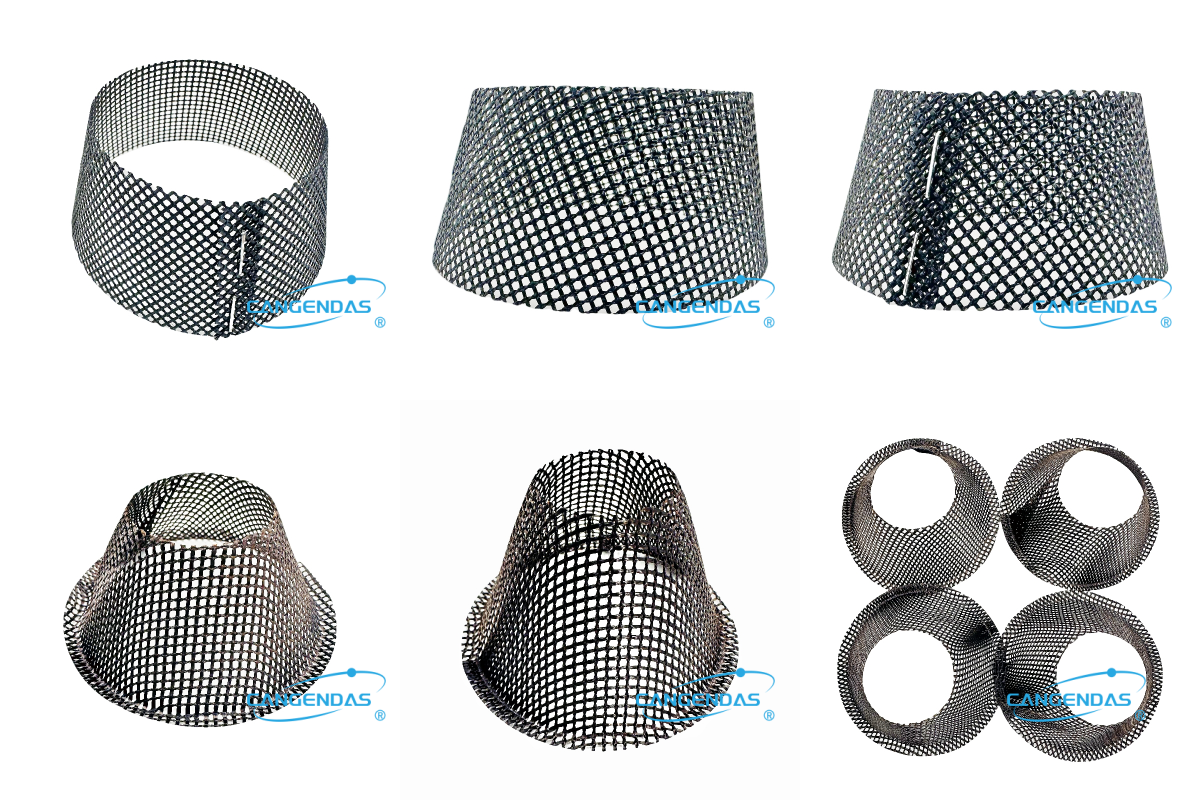

● Cutting mesh (brown, coated with resin): Square, round, fan and other heteroideus mesh cutted just according to client’s requirements. Used for filtering aluminum castings and placed in the gating system.

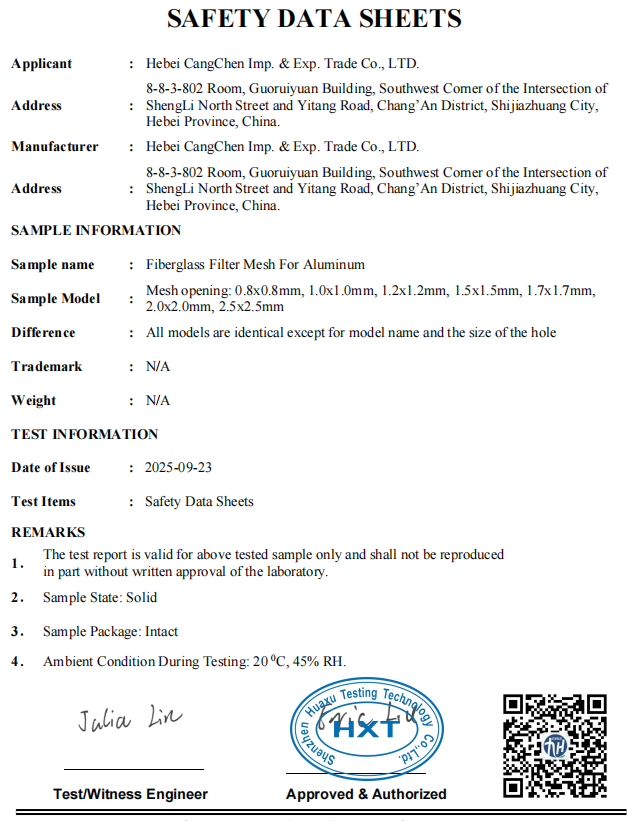

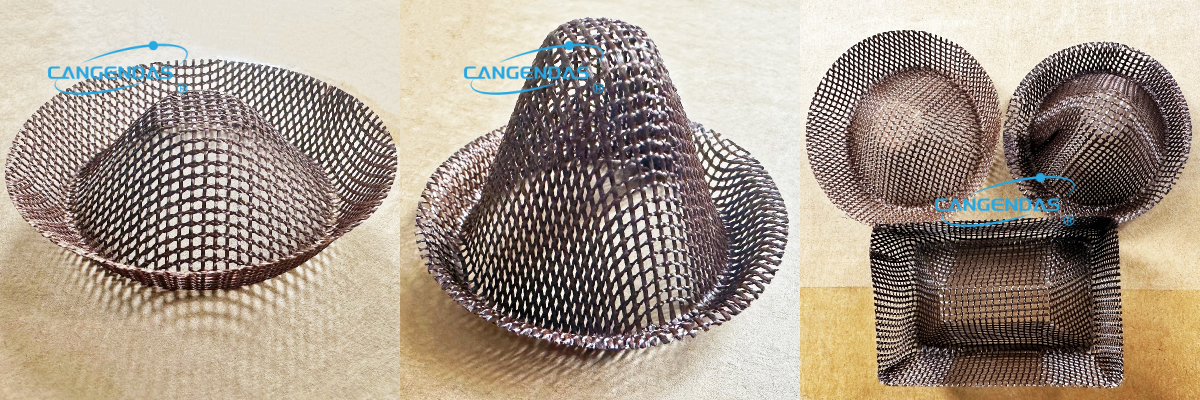

● Cylinder, cap and other special shapes (brown or black, coated with resin or carbonized): used for low pressure casting, such as aluminum alloy wheels, engine cylinder head and so on.

● Smokeless filters (black carbonization treatment): no combustion, smokeless, low gas output during the filtration process, for high quality requirements of casting production, such as aluminum alloy piston.

Cap type fiberglass filter mesh is usually a network structure, which is a non-metallic liquid metal purification device with the required mesh opening.

Its porosity is higher, the slag collection surface area is larger, and it can reduce the the Reynolds number of the mesh metal surface flowing through the cast filter, then it can make the filler be more stable and reduce the production of secondary oxidation slag in the mold.

For some castings that require high surface quality and good densification, in order to prevent inclusions and improve the internal quality of the castings, it is very necessary to install a cap type fiberglass filter mesh in the gate system.

Especially in the field of small and medium-sized castings such as automobiles, high-speed railways, machine tools and hydraulic parts, the purification effect of the cap filter mesh has been widely recognized by most foundry workers.

The usage of cap type fiberglass filter mesh can effectively remove liquid metal and non-metallic inclusions, improve the structure and mechanical properties of castings, improve the high quality standards of precision castings production and reduce the rate of casting defects. It can also reduce tool wear during machining and significantly improve efficiency. In addition, it can reduce porosity in the casting, reduce surface defects and reduce casting and filling lines, significantly increasing the process yield, which is much better than high silicon screen casting filters and cast filter products with straight holes.

Cone filter is no up and bottom sides, a special shape for aluminum filtration use!

Surface filtration: Surface filtration is a common metal liquid purification function of all casting filters.

● When the molten metal passes through the casting filter, unfloated or floating inclusions with a relatively large surface area, such as: molten slag, are captured by the surface of the casting filter.

● In addition, the captured inclusions will form a finer filter eye with the cast filter continue trapping subsequent inclusions, thus enhancing the filtration effect.

● However, at the same time of this surface filtration, with the decrease of the pouring temperature and the increase of the viscosity of the molten metal, as well as the extension of the pouring time, the cap filter mesh will be blocked to varying degrees, thus make filtering effect be worse.

So, the cap filter mesh should be replaced with a new one according to actual casting scenario to keep its best filtering effect.

It is divided into working temperature and softening temperature.

1. The working temperature of aluminum water filter is 700~800°C.

2. The softening temperature is 900°C.

We need to choose the suitable filter according to the different pouring temperatures of liquid aluminum, rather than let the filter working temperature affect the pouring temperature of the liquid metal in turn, which will cause more casting defects and lose the meaning of filtration.

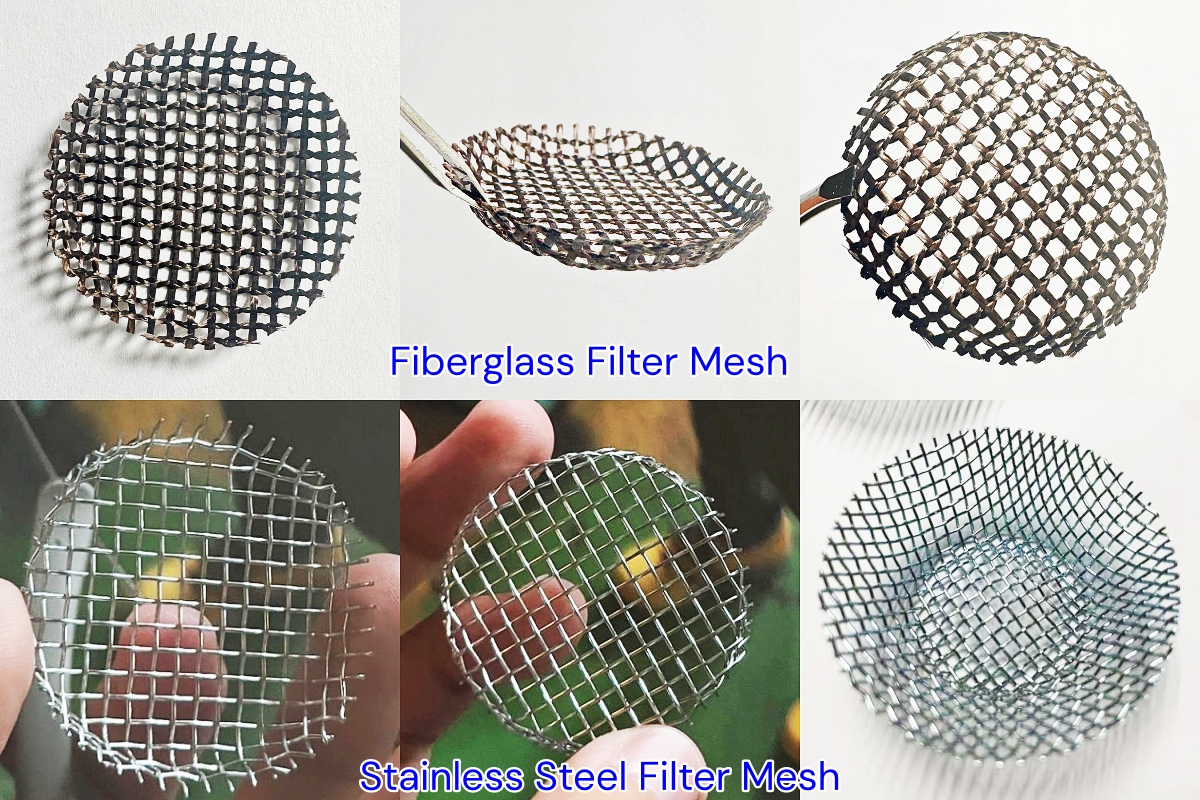

Are you looking for such filters for your aluminum liquid filtration?

Or are you looking for fiberglass material to replace your present stainless steel type?

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation