Apr. 29, 2025

Fiberglass filtration mesh is made of high temperature resistant fiber, woven and processed by special technology. There are kinds of products series with advanced technology and stable quality.

Compared with other types of filters, fiberglass casting filter is cheap, easy to use, does not change the metal composition of the casting, has good slag filtering effect and low gas generation.

In addition, it also has high temperature resistance, ablation resistance, good chemical stability, resistance to metal melt erosion and good steel strength.

In casting production, steel castings, iron castings, aluminum castings and other alloy castings are prone to quality problems such as slag holes, sand holes and gas holes due to various reasons. Therefore, the removal of non-metallic inclusion in metal melt is of great technical and economic value to improve the yield of castings and the quality of castings.

Fiberglass filtration mesh is an ideal filter material for various metal melts. It can also be used for the filtration of chemical corrosive liquids and high temperature gases.

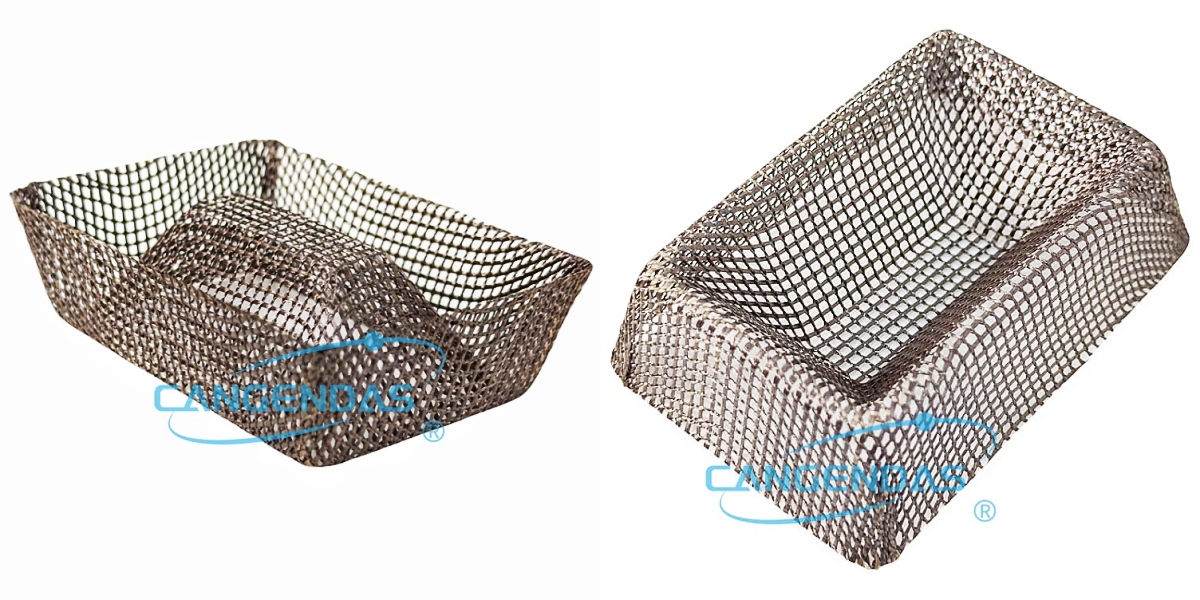

Fiberglass Cap Filter Mesh is usually a network structure, which is a non-metallic liquid metal purification device with the required mesh opening. Its porosity is higher, the slag collection surface area is larger, and it can reduce the the Reynolds number of the mesh metal surface flowing through the cast filter, then it can make the filler be more stable and reduce the production of secondary oxidation slag in the mold.

The usage of Fiberglass Cap Filter Mesh can effectively remove liquid metal and non-metallic inclusions, improve the structure and mechanical properties of castings, improve the high quality standards of precision castings production and reduce the rate of casting defects. It can also reduce tool wear during machining and significantly improve efficiency. In addition, it can reduce porosity in the casting, reduce surface defects and reduce casting and filling lines, significantly increasing the process yield, which is much better than high silicon screen casting filters and cast filter products with straight holes.

For some castings that require high surface quality and good densification, in order to prevent inclusions and improve the internal quality of the castings, it is very necessary to install an Fiberglass Cap Filter Mesh in the gate system.

Especially in the field of small and medium-sized castings such as automobiles, high-speed railways, machine tools and hydraulic parts, the purification effect of Fiberglass Cap Filter Mesh has been widely recognized by most foundry workers.

The Fiberglass Cap Filter Mesh is made of high temperature resistant fiberglass by special process weaving and post-treatment. Products have become serialized, advanced technology, stable quality. Compared with other types of cap type filter, the lower cost, easy to use, does not change the composition of the casting, good slag filtration effect and small air volume have already attracted all clients from the world attention and choose.

The Fiberglass Cap Filter Mesh cost is cheap, easy to use, it can improve the mechanical properties of castings without changing the metal composition, improve the production quality of castings. At the same time, it is resistant to high temperature and ablative properties, and it can operate at temperatures of about 850 degrees.

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation