Sep. 30, 2025

Zirconia Ceramic Foam Filters are used for filtration of all types of steel, such as: unalloyed, low alloyed, stainless and high-alloyed.

● The basic material of zirconia foam ceramic filter is ZrO2.

● The heat resistance temperature higher than about 1760℃.

● With high strength and excellent high-temperature impact resistance.

Cast steel parts are widely used in aspects that require high strength and elongation requirements. Therefore, cast steel parts are very sensitive to defects caused by impurities.

The excellent characteristics of zirconia foam ceramic filter can effectively remove impurities that ultimately lead to product quality defects.

The impurities mainly consist of non-metallic particles, slag, and refractory material fragments.

It improves the surface quality and mechanical properties of the casting parts, reduces the scrap rate.

Zirconia foam ceramic filter can make the molten steel fill the cavity more uniformly.

During pouring, the molten metal has a higher tendency for turbulence, and the turbulence after passing through the three-dimensional pore structure of zirconia foam ceramic filter is ultimately converted into a very stable laminar flow. The laminar flow has better filling properties for the cavity, thereby reducing the impact and corrosion of the molten metal solution on the casting cavity and significantly reducing the scrap rate.

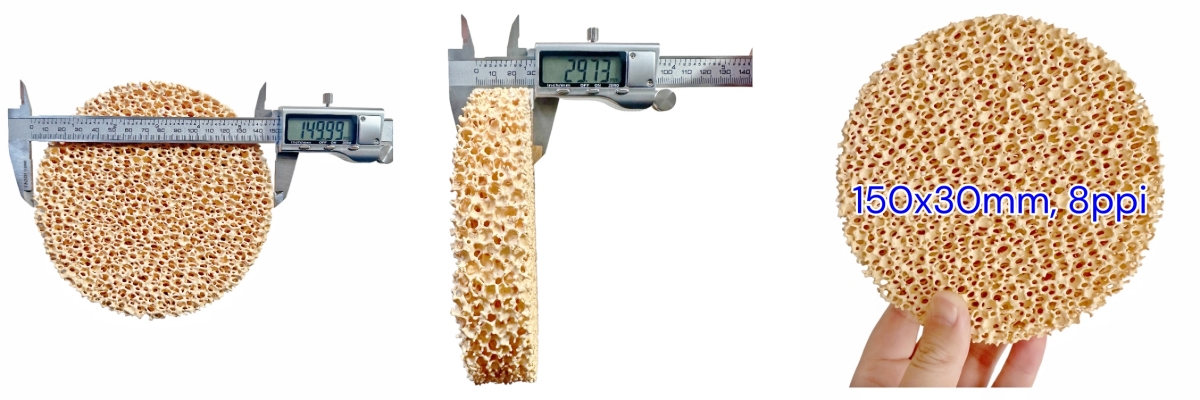

Today, 150x30mm, 8ppi Zirconia foam ceramic filters are ready to deliver to our Slovenia client!

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation