Jul. 14, 2025

A fiberglass filtration mesh filter is a type of filter made from woven or non-woven fiberglass materials, designed to efficiently filter and separate particles from liquids or gases. It is commonly used in various industrial and commercial applications where fine filtration is required, especially in environments where other types of filters (like paper or cloth) may not offer the same level of performance or durability.

It is filter for alumina casting woven with special high-twist & high-strength alkali-free fiberglass and special post-treatment. The maximum temperature resistance can reach 900 ℃.

Widely used in automobile and motorcycle wheels, cylinder pistons, aluminum rods, aluminum materials, aluminum ingots, aluminum plates and precision casting of all types of aluminum alloy casting.

Material: Primarily made from alkali-free or high-silica fiberglass yarn (E-glass is common). These are inorganic, non-metallic materials.

Weaving: The fiberglass yarns are woven into a mesh fabric, creating a precise and consistent pore structure. Common weave patterns include plain or leno.

Treatment: The woven mesh is often treated with special coatings, such as high-temperature resistant resins (e.g., phenolic resin, epoxy resin) or carbonized through high-temperature processes. This treatment enhances its rigidity, strength, and resistance to erosion from molten metals. It can also make them smokeless, odorless, and flameless during filtration.

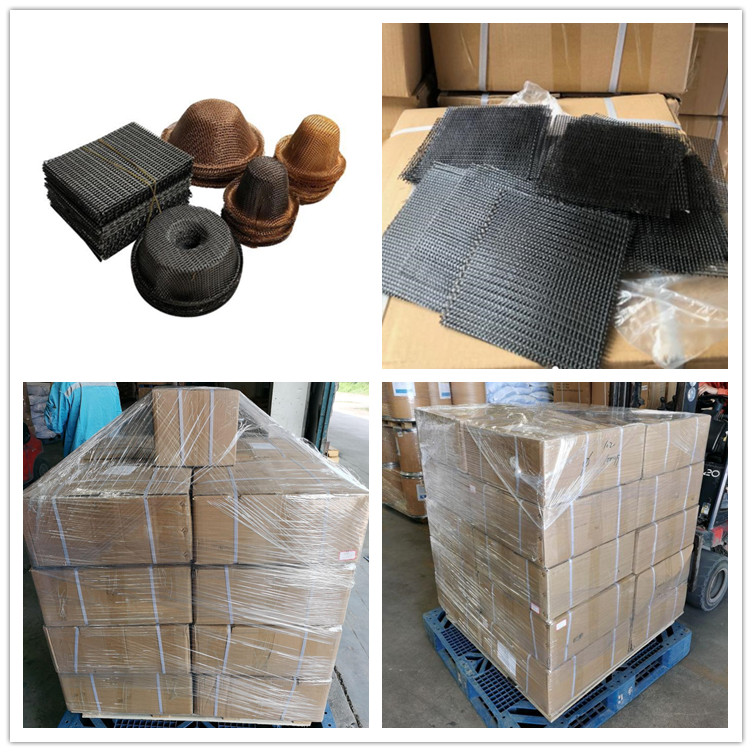

On 15th. Oct. 2021, 10 pallets fiberglass filtration mesh are delivered to our Indonesia clients, they are one of our customers with long-term cooperation. The feedback information from them are always perfect.

Aluminum and Aluminum Alloys: Widely used in continuous casting, semi-continuous casting, sand casting, permanent mold casting, die casting, investment casting, and other processes for producing ingots, rods, plates, profiles, and precision parts (e.g., automotive wheels, engine cylinder heads, pistons).

Iron Castings: Used for filtering gray iron, ductile iron, and other iron alloys.

Steel Castings: Applied in filtering molten steel, particularly for small to medium-sized steel castings.

Copper and Copper Alloys: Employed for purifying molten copper, brass, and bronze.

Improved Casting Quality: Reduces defects like slag holes, sand holes, gas holes, and surface imperfections.

Enhanced Mechanical Properties: Leads to castings with better tensile strength, elongation, and overall integrity.

Increased Casting Yield: Minimizes scrap rates by preventing contaminated metal from entering the mold and ensuring a more complete fill.

Smoother Mold Filling: Promotes consistent and laminar metal flow, preventing air pockets and improving the final part's structure.

Environmental Benefits: Some types (carbonized) offer smokeless filtration.

High Temperature Resistance: Fiberglass mesh filters are designed to withstand the extreme temperatures of molten metals, often up to 800−900℃ for aluminum, 1200 ℃ for copper, 1400−1450 ℃ for iron, and even 1600−1620 ℃ for steel. High-silica fiberglass variants can tolerate even higher short-term temperatures (e.g., 1400 ℃).

Chemical Stability: Excellent resistance to corrosion and chemical reactions with molten metals. They do not contaminate the filtered liquid.

Mechanical Strength: Possess good tensile strength and rigidity, especially after resin treatment, allowing them to withstand the flow and impact of molten metal without deforming or tearing.

Filtration Efficiency: Effective in capturing and removing various impurities like oxides, slag, non-metallic inclusions, refractory particles, and dross, even down to micron sizes.

Reduced Turbulence: The mesh structure helps to create a smoother, more laminar flow of molten metal, reducing turbulence and air entrapment in the mold.

Cost-Effectiveness: Generally more economical compared to some other filter types like ceramic foam filters, especially for smaller casting applications.

Easy to Use: Lightweight, easy to cut, and can be customized into various shapes (square, round, cap-style, cylindrical, etc.) to fit different gating systems.

Low Gas Generation: Treated filters, especially carbonized ones, produce minimal smoke and gas during filtration, contributing to a cleaner casting environment and fewer gas-related defects in the final product.

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation