Jan. 13, 2026

The aluminum liquid is divided to two ends of ingot through the bags, this process will determines the temperature distribution around crystallizer device. And the metallographic structure of the cured aluminum alloy ingot will be affected by the temperature distribution.

The second purpose is to keep and leave the oxide in the bag, reduce the aluminium liquid flow and filter out all the large particles that mainly include alumina, chloride and titanium, boron, magnesium oxide and large resistant material shed.

Fiberglass Filtration Combo bag is one of process in contact with aluminum liquid in casting foundry, so it is quite important. It is the key to achieve the casting quality standards of aluminum and aluminum alloy flat ingot if bags and skimming ring are used together.

● Apply to filter large diameter aluminum ingot and billet, rectangular aluminium slab, and aluminum-alloy casting parts.

● Improve the temperature distribution of molten metal and control flow of aluminium vertical direct.

● Improve working environment, bags will be producing very little smoke, fumes or flame when molten aluminium flow inside, but it is harmless, no any affect to staff.

● Filter molten metal and decrease in non-metallic inclusions and oxide films in liquid metal.

● Improve mechanical quality of aluminum casting product.

● Improve the hardness of aluminum casting product with more average surface hard and bending strength.

TF is abbreviated form of thermally fused, full name: Fiberglass thermally fused shunt combo bag!

It is weaved by special high-twist & high-strength alkali-free fiberglass yarn, special post-treatment, coated with special phenolic resin and carbonized by high temperature.

Its withstand temperature up to 1000 °C.

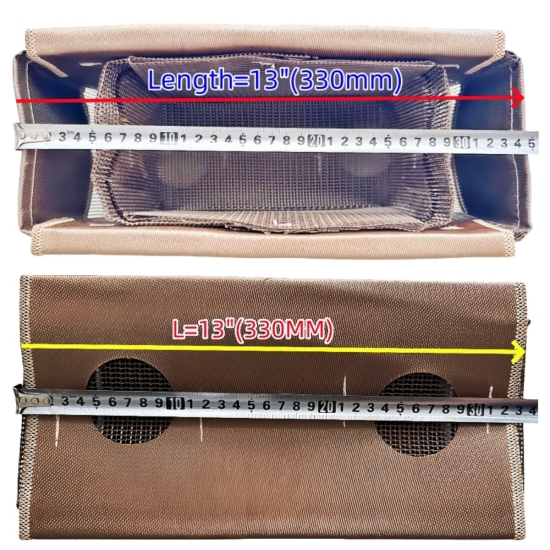

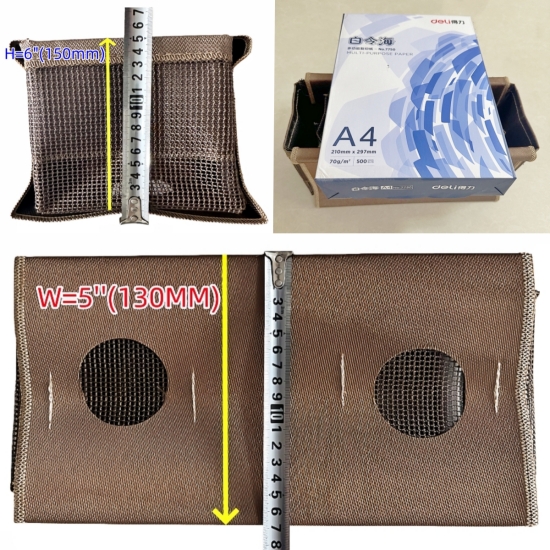

Basic structure is: Much tighter fabric surround the small fiberglass woven frame inside.

Normal size: 13"x5"x6"(330x130x150mm) L*W*H

| Type | TF Combo Bag For Aluminum |

| Work Temperature | ≤1000℃ |

| Melting Point | 1100℃ |

| Color | White, Brown and Yellow |

| Outside fiberglass cloth yarn diameter and weight | 0.2mm, 420g/m2 |

| Inside fiberglass cloth yarn diameter and weight | 0.45mm, 350g/m2 |

| Normal Dimensions | 13" X 5" X 6", 18" X 5" X 6", 18" X 10" X 6" |

| Mesh Openning | 2.0x2.0/2.5x2.5mm and special specifications can be customized. |

| Application | Filtration & Shunt For All Aluminium and aluminium alloy products. |

| Work Time: | 4hours when flow ≤10 kg/min. |

| 1.5hours when flow ≤120 kg/min. | |

| Tensile Strength | 8KGS |

| Filter fineness | 5-50(μm) |

| Filter area | 100(m2) |

| OEM | Size, Shape, Logo and package can be customized according to client's drawing or samples. |

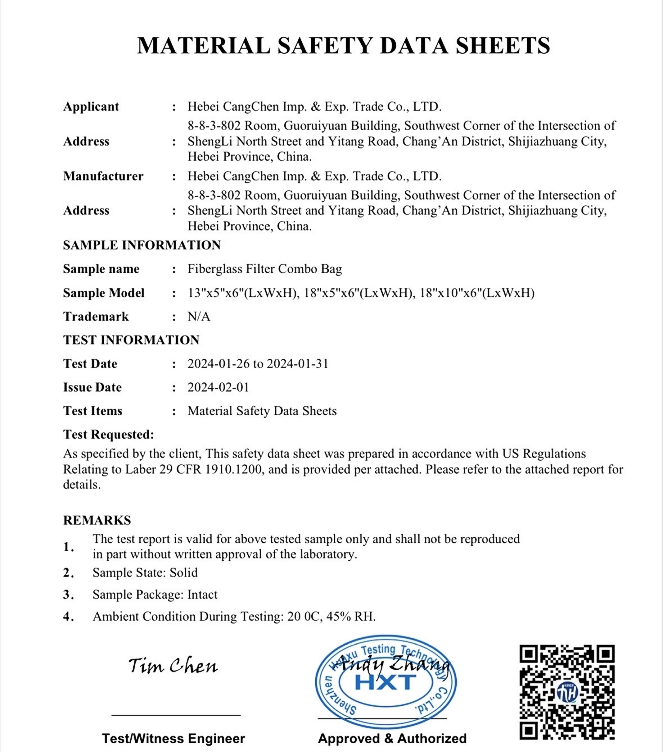

| Certificate | MSDS |

| ISO9001:2015/ISO14001:2015/ISO45001:2018 |

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation