Nov. 22, 2022

Silicon Carbide (SiC), Alumina (Al₂O₃), Zirconia (ZrO₂), and Honeycomb Extruded Ceramic Filters are advanced high-temperature filtration solutions widely used in molten metal filtration, especially for aluminum, cast iron, and non-ferrous alloys. These ceramic filters are engineered to remove non-metallic inclusions, oxides, and slag, ensuring cleaner molten metal flow and significantly improving casting quality.

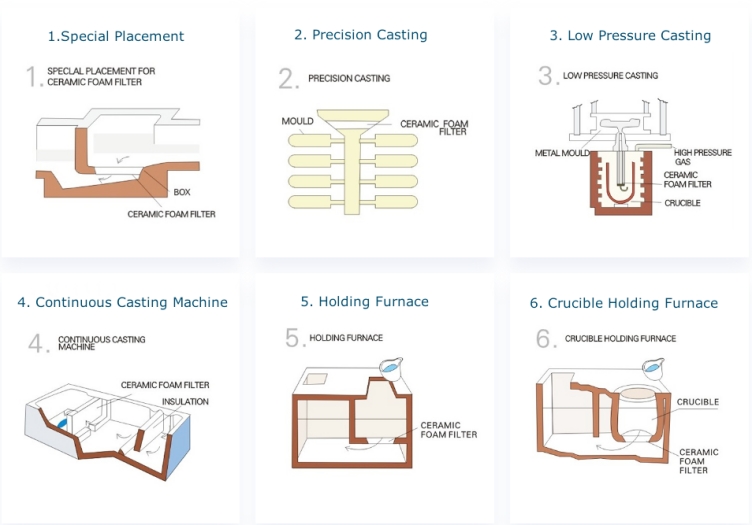

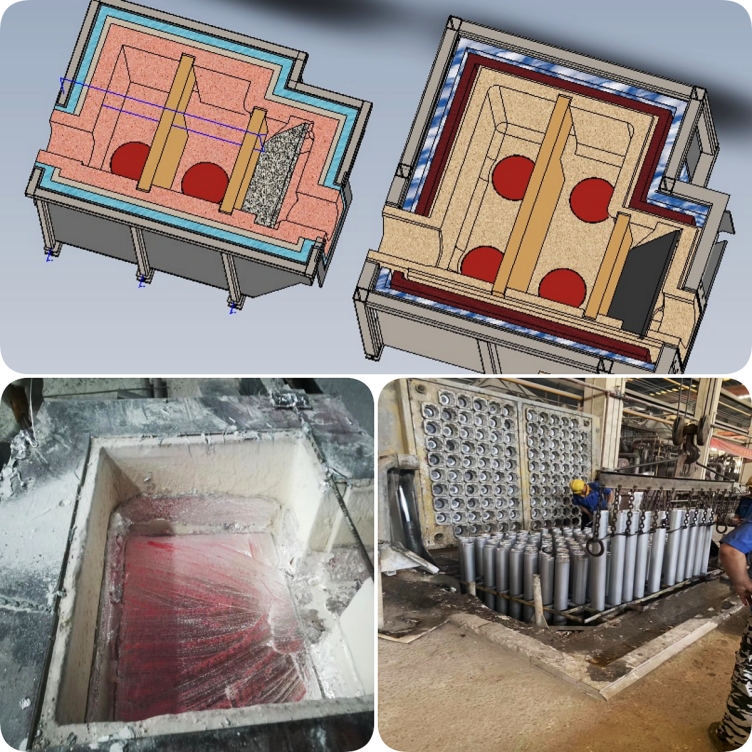

Ceramic foam filter is a kind of effective molten metal filter.

It's three-dimensional connected mesh skeleton structure and high porosity makes it has many advantages, large surface area of slags collection, large inner surface area of filtering, small flow resistance, good filtering effect,etc.

Ceramic Foam Filters can remove metal slag and solution of metal impurities, which are far stronger than several of the other filters. It filters them with a combination of physics and chemistry.

● Physical Way: The physical screen can filter large inclusions in the mesh surface.

● Chemical Way: Intercept tiny inclusions in the role of chemical affinity and be attracted to the filter surface, side walls or pores. Therefore, to filter out effectively impurities of various sizes, including much smaller than the pores of the filter impurities.

Filter in above ways and comb the whole disordered molten metal flow, reducing turbulence, making the molten metal flow to be smooth and clean.

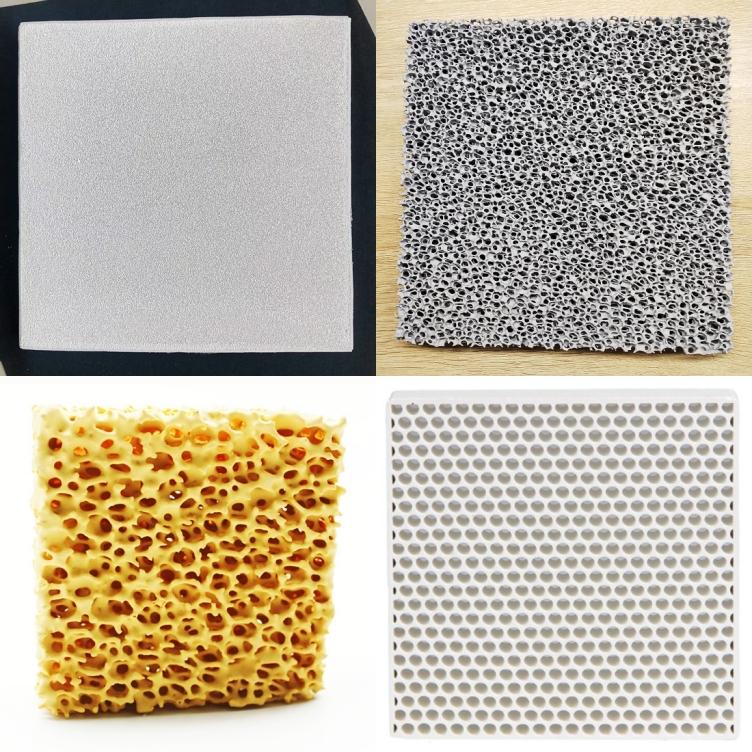

In accordance with its material, ceramic foam filter can be divided into Silicon Carbide, Alumina, Zirconia and Honeycomb extruded ceramic filter.

Excellent thermal shock resistance, high mechanical strength, and outstanding corrosion resistance. Ideal for demanding aluminum and iron casting applications.

High purity and chemical stability, suitable for aluminum alloy filtration with consistent pore structure and reliable performance.

Superior high-temperature resistance and thermal insulation, designed for extreme casting environments and high-value alloy applications.

Precision-extruded channel structures provide low flow resistance, uniform metal flow, and high filtration efficiency, making them ideal for continuous casting and large-volume production.

| Ceramic Foam Filter | Material | ||||

| Items | Unit | Alumina | Silicon Carbide | Zirconia | Mullite honeycomb ceramic filter plate |

| Color | Color | White | Grey Black | Yellow | White |

| Composition | Al2O3 | ≥85 | ≤30 | ≤30 | ≥55 |

| SiO2 | ≤1 | ≤10 | ≤4 | ≥34.5 | |

| Others | -- | SiC ≥60 | ZrO2 ≥66 | MgO ≥6.8 | |

| Channels Density | ppi | 10~60 | 10-60 | 10-60 | -- |

| Porosity | % | 80~90 | 80~90 | 80~90 | 40-60 |

| Bending Strength | Mpa | >0.6 | >0.8 | >1.0 | -- |

| Compression Strength | Mpa | >0.8 | >0.9 | >1.2 | 6.5 |

| Volume-Weight | g/cm3 | 0.3-0.45 | 0.35-0.5 | 0.9-1.5 | -- |

| Max Operation Temperature | °C | ≤1100 | ≤1500 | ≤1700 | ≤1480 |

| Thermal shock resistance | Times/1100°C | 6 | 6 | 6 | 6 |

| Application | Filtration of molten aluminium.Non-ferrous alloys. | Filtration of molten steel and alloy, large scale iron casting. | Filtration of molten steel and steel alloys. | Filtration of Ductile iron, gray cast iron, aluminum casting | |

| Manufacturer | Hebei CangChen Imp. & Exp. Trade Co., Ltd. | ||||

| Certificate | ISO9001:2015 | ||||

Also, we can customize all types just according to your own need, any need, please do not hesitate to contact us, we will give you prompt reply as soon as possible.

Round Fiberglass Filter Mesh For Recycled Aluminium Melt

Jan. 28, 2026

Fiberglass Filter Mesh Are Exported To Our Abroad Client

Jan. 14, 2026

TF COMBO BAG to filter aluminum ingot and billet

Jan. 13, 2026

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation