Oct. 29, 2022

Alumina ceramic foam filter plate is mainly used in the melting filtration of aluminum and aluminum alloys.

It can efficiently filter residues such as oxide slag, oxide scale, non-metallic inclusions and gate groove linings in molten aluminum, and solve the problem of aluminum and aluminum alloys being sensitive to internal defects. The unique production process and detection method make the alumina filter plate with high opening rate, uniform pore structure and high surface strength.

Available in 7" to 26", mesh up to 60ppi filter plates.

Basic Technical Data Sheet

| Items | Bulk Density (g/m3) | Rupture Modulus(820℃/Mpa) | Compression Strength Under Normal Temperature(Mpa) | Refractory temperature(℃) | Thermal Expansion of Sealing Gasket(℃) |

| Typical Value | >0.45 | >5.5 | >0.8-1.0 | ≥1500 | >400-500 |

Aperture Size(The total holes quantity of random 25.4mm length.)

| Mesh (ppi) | 10 | 20 | 30 | 40 | 50 | 60 |

| Hole Density | 8-12 | 18-23 | 28-33 | 38-43 | 48-53 | 58-63 |

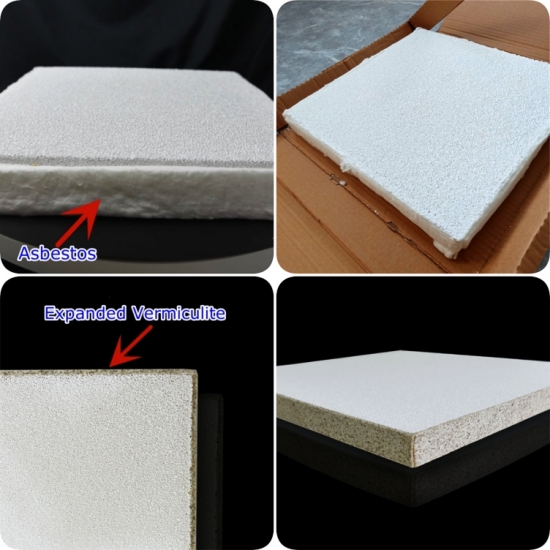

Two kinds of sides cutting: One is right-angle side, the other is bevel edge.

Two kinds of sealing gaskets: one is asbestos hemming, the other is with expandable gasket, also named expanded vermiculite.

All specifications can be suctomized for you only, please let us know if you are intereted in it?

Manufacturing process

The organic foam sponge with three-dimensional network structure and connected pores is used as the carrier, which is infiltrated into the special ceramic slurry with thixotropy, and a special rolling process is adopted to make the ceramic slurry evenly spread on the skeleton of the carrier, and then finished by roasting at high temperature after drying curing.

Using method

● Clean filter box

● Gently put the filter plate into the filter box, and press the sealing gasket around the filter plate by hand to prevent the flow of molten aluminum.

● Evenly preheat the filter box and filter plate to make it close to the temperature of the molten aluminum. Preheat to remove moisture and facilitate initial instant filtration. Preheating can be carried out using electric or gas heating. Under normal circumstances, it takes about 15--30 minutes.

● Pay attention to the change of the aluminum hydraulic head during casting. The normal initial pressure head is 100-150mm. When the molten aluminum begins to pass, the pressure head will drop below 75--100mm, and then the pressure head will gradually increase.

● During the normal filtration process, avoid knocking and vibrating the filter plate. At the same time, the launder should be filled with molten aluminum to avoid too much disturbance of the aluminum liquid.

● After filtration, take out the filter plate in time and clean the filter box.

Round Fiberglass Filter Mesh For Recycled Aluminium Melt

Jan. 28, 2026

Fiberglass Filter Mesh Are Exported To Our Abroad Client

Jan. 14, 2026

TF COMBO BAG to filter aluminum ingot and billet

Jan. 13, 2026

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation