Sep. 12, 2024

On 10th., Sept. 2024, We had a formal meeting with clients from USA, who were focusing on our fiberglass combo filter bags.

Both of two parties deeply exchanged views and suggestions on how to better develop fiberglass combo filter bags in USA aluminium foundry.

● Clients provided a detailed introuduction about where the bags would be used for, there was a great prospect for such products.

● As a manufacturer of such bags, we absolutely promised the clients that we would provide the best quality and best competitive price and timely delivery.

● Meanwhile, Unique customized services is our core competitiveness. We could customized what clients needed.

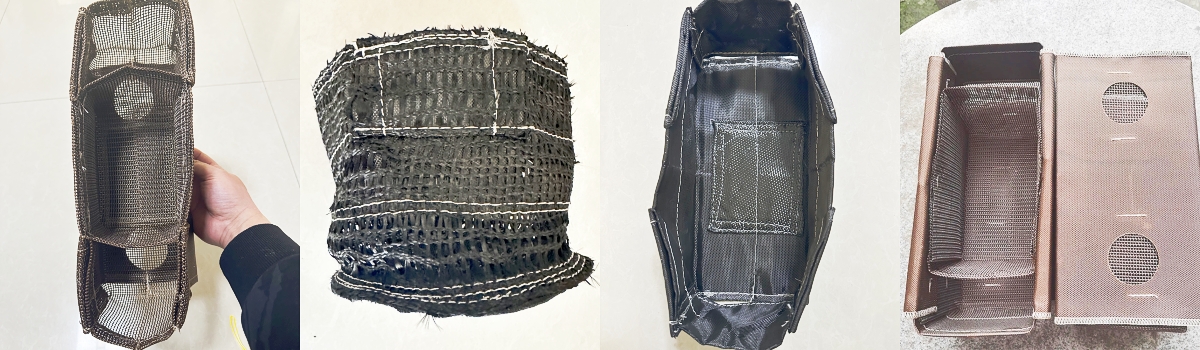

How does fiberglass combo filter be produced?

Weaved by special high-twist & high-strength alkali-free fiberglass yarn, special post-treatment, coated with resin and carbonized by high temperature. its withstand temperature up to 1000 °C.

What are its applications and functions?

● Apply to filter and evenly distribute molten aluminum in molds.

● Apply to filter large diameter aluminum ingot and billet, rectangular aluminium slab, and aluminum-alloy casting parts.

● Used in sand casting, permanent mold, shell mold, draw mold and investment casting, which can remove impurities, reduce turbulence, eliminate air bubbles, thereby improve casting quality and reduce production costs.

● Improve the temperature distribution of molten metal and control flow of aluminium vertical direct.

● Improve working environment, bags will be producing very little smoke, fumes or flame when molten aluminium flow inside, but it is harmless, no any affect to staff.

● Filter molten metal and decrease in non-metallic inclusions and oxide films in liquid metal.

● Improve mechanical quality of aluminum casting product.

● Improve the hardness of aluminum casting product with more average surface hard and bending strength.

● Ensure the removal of oxides or other debris suspended in the volume.

What are the advantages of fiberglass combo filter bag?

Comparing to other filter bags, it does not affect the component of aluminum alloy, and with good filtration effect, high temperature resistance, high strength, excellent acid and alkali resistance, non-stick aluminum, non-slagging, non-peeling, as well as easy installation.

● New environmental protection material, does not burn during whole use process , no harm to human body.

● Advanced production equipment, warp and weft standard for base cloth, high temperature resistant coating mesh uniform, the finished product is exquisitely made without burrs.

● Both sides of the bag adopt square hole fixing device technology, more convenient operation and improve the working rate.

F.A.Q. From Our Clients:

1. What is the dimension of this bag used for alumium casting filtration?

Usually out dimensions: 13" x 5"x 6", mesh openning is 2.5x2.5mm, but any dimensions can be customized according to your requirements.

2. Can we get free samples to test?

Of course, we will provide free samples to test, but freight need to be paid by clients.

3. What is the productivity of this bag?

Usually, 10,000pieces per month, if urgent orders, 1-30,0000 pieces also can be produced per month.

4. What is the certification of company and for products?

ISO9001:2015 and MSDS.

Hebei Cangchen, a professional manufacturer of such filter bags, we have our own registered trademark: "CANGENDAS", but also we have OEM service for all customers from the world.

We are a professional factory with ISO certification and our fiberglass combo filter bags have been certified by MSDS(USA).

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation