Apr. 22, 2025

Alumina foam ceramic is a kind of foam material made from high purity alumina. The foam ceramics have the characteristics of uniform porosity, high temperature resistance, heat shock resistance, wear resistance and chemical stability.

Alumina Ceramic foam filter plate is produced with the organic foam sponge with three-dimensional network structure and connected pores is used as the carrier, which is infiltrated into the special ceramic slurry with thixotropy, and a special rolling process is adopted to make the ceramic slurry evenly spread on the skeleton of the carrier, and then finished by roasting at high temperature after drying curing.

Alumina Ceramic foam filter plate can effectively remove all kinds of inclusions with fineness up to micron level in aluminum liquid, make aluminum liquid into a steady laminar flow, which is conducive to filling.

It has a unique mullite-corundum structure, good mechanical strength and chemical stability, excellent resistance to aluminum liquid erosion performance.

It can obtain stable filtration effect by strict control of hole size and through hole rate.

The ceramic foam filter plate is surrounded by a sealing ceramic fiber liner, which facilitates the seal of the filter plate in the filter box to ensure that there is no metal liquid sideflow.

The dimensions which are commonly used in the production of aluminum and aluminum alloys: 178×178×50mm, 230×230×50mm, 305×305×50mm, 381×381×50mm, 432×432×50mm, 508×508×50mm, 584×584×50mm, a total of seven main specifications of foam ceramics Filter plate products.

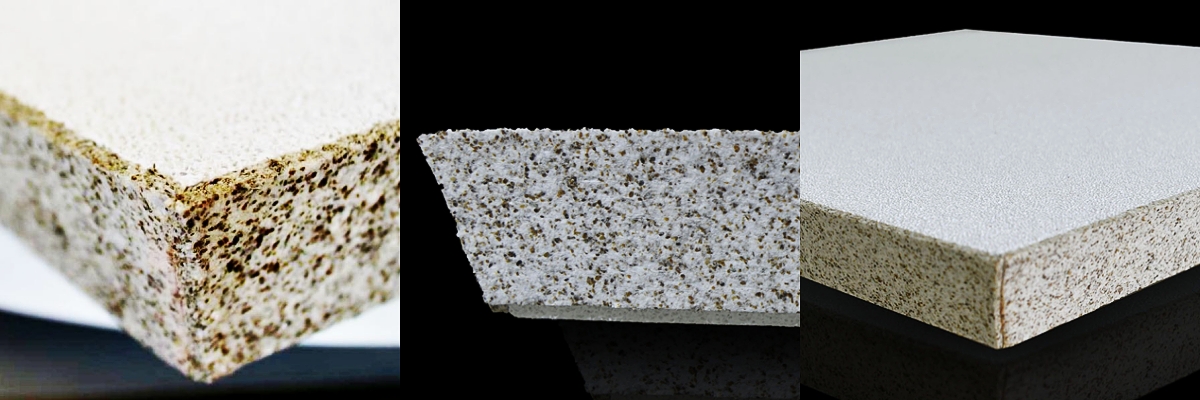

The First one is no any side gaskets, usually used for Kitchen hood exhaust:

The Second is with asbestos gasket:

The Third is with fiber paper gasket:

The Fourth, also the most expensive one is with expanded vermiculite gasket:

Alumina Ceramic foam filter plate is mainly used in the purification process of aluminum and aluminum alloy production, but also used as a variety of gas-solid, liquid-solid separation media, catalyst carrier, burner and sound absorption and environmental protection fields.

The other applications under high temperature conditions, Alumina Ceramic foam filter plate have excellent thermal radiation characteristics, which are used to enhance heat transfer and combustion technology in porous media with remarkable results.

Alumina Ceramic foam filter plate can also be made into a photocatalyst carrier, coated with nano titanium dioxide on the foam ceramic carrier, excited by ultraviolet light, has strong photocatalytic oxidation and degradation characteristics, can catalyze the degradation of organic matter and microorganisms, so as to purify the air.

Alumina Ceramic foam filter plate can also be made into chemical tower packing, gas distribution materials, gas stove energy-saving combustion plate.

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation