Aug. 14, 2023

We, Hebei Cangchen, a professional foundry filtration products manufacturer who focuses on the production, sales, service and solutions.

We are the recognized leader in the development and production of casting filters at home and abroad, and possesses the excellent innovation capabilities in filter manufacturing technology.

Our products are recognized and purchased by more and more customers. Why? There are some key points as follow:

● "Always Better" is our Business Philosophy. We insist on "Professionalism & Innovation", helping customers improve the castings quality and reduce production costs, also make progress and development together with them.

● Hebei Cangchen, as a professional and experienced supplier, not only customize the casting filtration products to those who have their own brand, but also customize the solutions and service to them.

● Since founded in 2002, with excellent quality and continuous design innovation, we have successfully opened the international market, cooperated with a large number of clients all over the world.

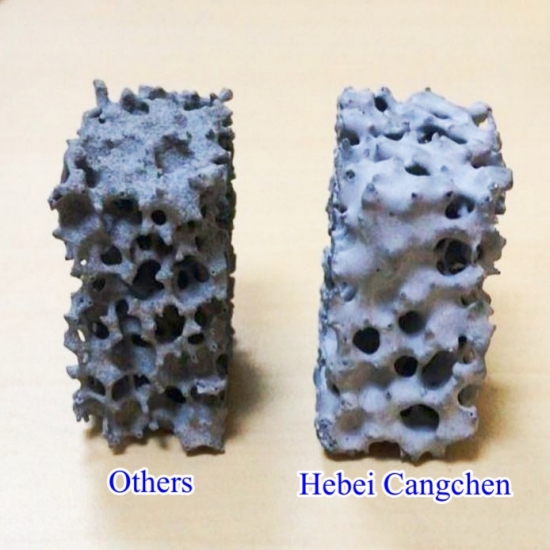

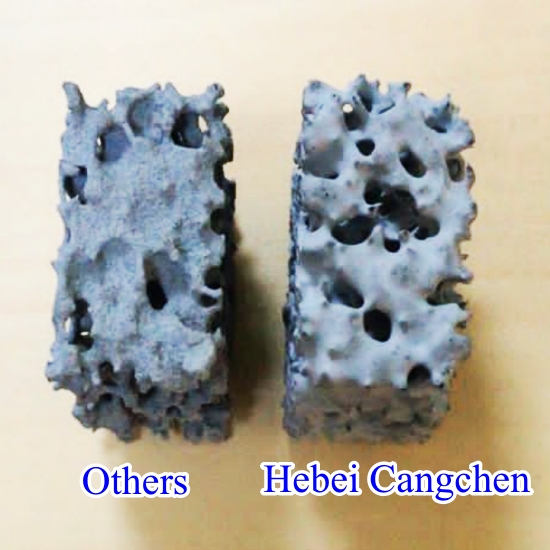

You can get your own comments from the comparation of the following ceramic foam filters pictures which are sent by our clients:

● Picture 1: Compared from color

● Picture 2: Compared from porosity

● Picture 3: Compared from dimensions

Our ceramic foam filters feature a uniform 3D interconnected pore structure that effectively captures non-metallic inclusions, oxides, and slag particles. This ensures a cleaner melt and significantly improves casting quality and yield.

Made from high-purity alumina, zirconia, or silicon carbide materials, our filters can withstand extreme temperature fluctuations during molten metal pouring without cracking or deforming.

Through advanced manufacturing and controlled sintering processes, our ceramic filters maintain high compressive and flexural strength, providing reliable stability even under high metal flow conditions.

We provide custom sizes, shapes, and pore densities (10–60 PPI) to suit various casting processes—gravity casting, low-pressure casting, or high-pressure die casting—offering flexibility for diverse foundry requirements.

By removing impurities and minimizing turbulence, our filters enhance the mechanical properties, surface finish, and overall performance of the final metal products.

Cleaner metal leads to fewer defects and less rework. Our ceramic foam filters help foundries achieve higher efficiency, reduce material waste, and optimize production costs.

Every batch of filters undergoes strict quality inspection and dimensional accuracy control, ensuring stable performance and long service life in demanding industrial applications.

With a strong production capacity and global export experience, we ensure on-time delivery, stable supply, and technical support to our clients worldwide.

Why do more and more clients choose our Ceramic Foam Filters? We believe you have had a quite clear answer in your mind now, any need, please contact us.

Round Fiberglass Filter Mesh For Recycled Aluminium Melt

Jan. 28, 2026

Fiberglass Filter Mesh Are Exported To Our Abroad Client

Jan. 14, 2026

TF COMBO BAG to filter aluminum ingot and billet

Jan. 13, 2026

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation