Jul. 24, 2025

SIC ceramic foam filter produced by our company adopts imported raw materials from Japan and advanced laser cutting technology, which can meet the requirements of manual modeling and mechanized production line with higher efficiency, and ensure the quality standard requirements of casting factory productization.

Excellent raw materials and advanced production technology ensure quite stable dimensional tolerance of our ceramic foam filters.

SIC ceramic foam filter with foam sponge three-dimensional mesh interworking structure can make the metal liquid reflect the rectification, mechanical screening, filter cake, adsorption filtration mechanism to effectively improve the purity of metal liquid, reduce scrap rate, reduce machining losses so as to improve production efficiency and reduce production costs.

SIC ceramic foam filter has the characteristics of high strength, good thermal stability, large specific surface area and high dimensional accuracy.

SIC ceramic foam filter mainly used for filtering and purifying nodular cast iron, gray cast iron, aluminum, copper and other alloy metal liquid filtration.

SIC ceramic foam filter mainly used for nodular cast iron, gray cast iron, aluminum.

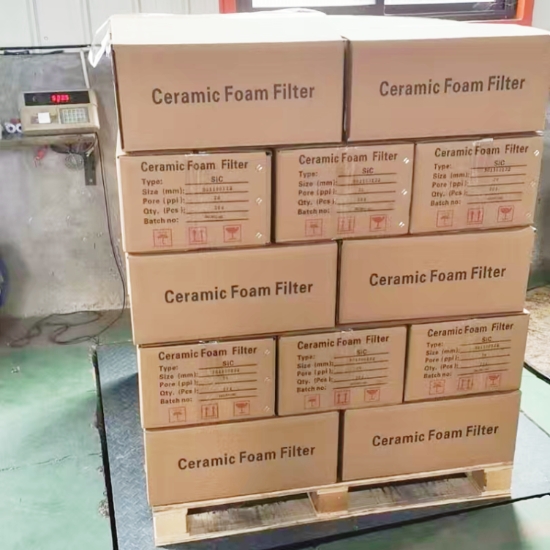

Today, one pallet of SIC ceramic foam filters is delivered to our South Africa client after many inspections!

SIC (silicon carbide) ceramic foam filters are developed and manufactured for the filtration of cast iron and non ferrous alloys. As the most advanced filter type with the higher filtration efficiency, It can effectively reduce inclusions and turbulence of molten metal, ensuring purified molten metal goes into the mould cavity with improved flow rates.

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation