Oct. 25, 2022

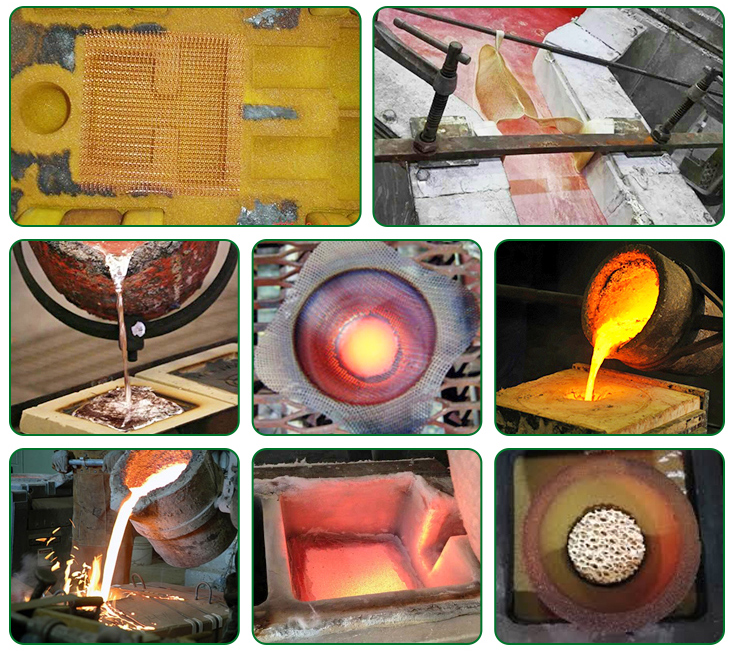

In casting production, the rejection rate of castings is 50 to 60% due to casting problems such as non-metallic inclusions.

The inclusions do not only reduce mechanical properties of the casting, but also has a great influence on processability and appearance.

The use of casting filters has become an important auxiliary material for purification of liquid casting alloys and reducing or filtering various non-metallic inclusions, then good quality castings can be obtained.

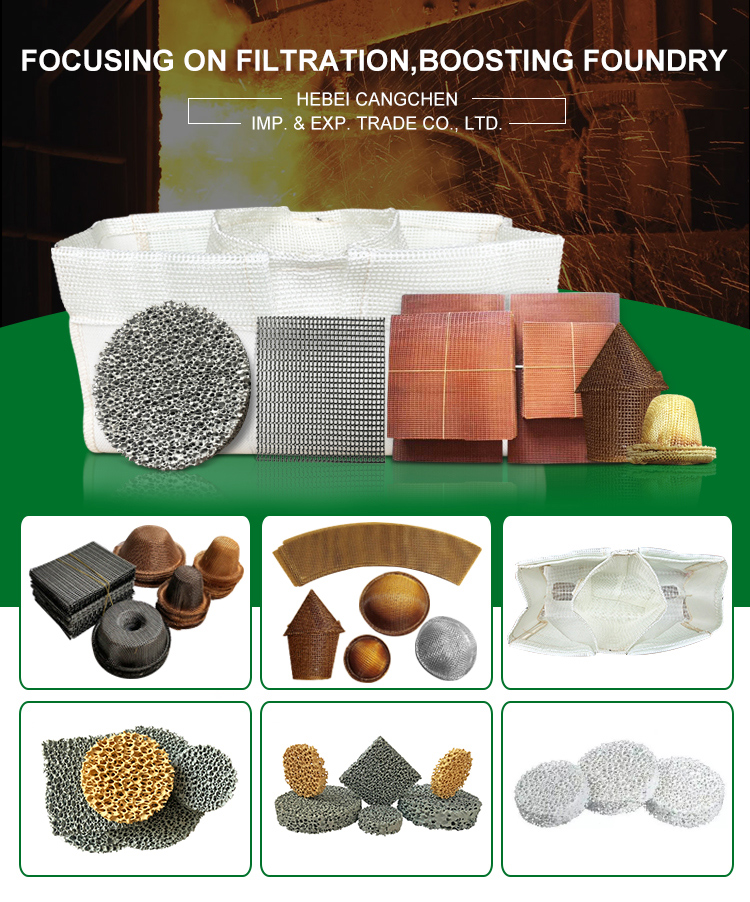

We, Hebei Cangchen, a professional foundry filtration products manufacturer who focuses on the production, sales, service and solutions. We are the recognized leader in the development and production of casting filters at home and abroad, and possesses the excellent innovation capabilities in filter manufacturing technology.

● all kinds of high silica fiberglass filter mesh,

● smokeless & odorless high temperature carbonized fiberglass filtration mesh,

● fiberglass filter bag and other heteromorphic filter mesh,

● ceramic foam filters including SIC, Alumina and Honeycomb extruded ceramic filter.

Since founded in 2002, with excellent quality and continuous design innovation, we have successfully opened the international market, cooperate with a large number of clients all over the world.

Looking forward to get inquiry of above products from you!

Round Fiberglass Filter Mesh For Recycled Aluminium Melt

Jan. 28, 2026

Fiberglass Filter Mesh Are Exported To Our Abroad Client

Jan. 14, 2026

TF COMBO BAG to filter aluminum ingot and billet

Jan. 13, 2026

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation