Nov. 20, 2025

Nowadays, fiberglass filter mesh is adopted to filter and purify metal liquids by casting industries.

It has become a more commonly used casting auxiliary material due to the characteristics of cheap cost, simple production and convenient use.

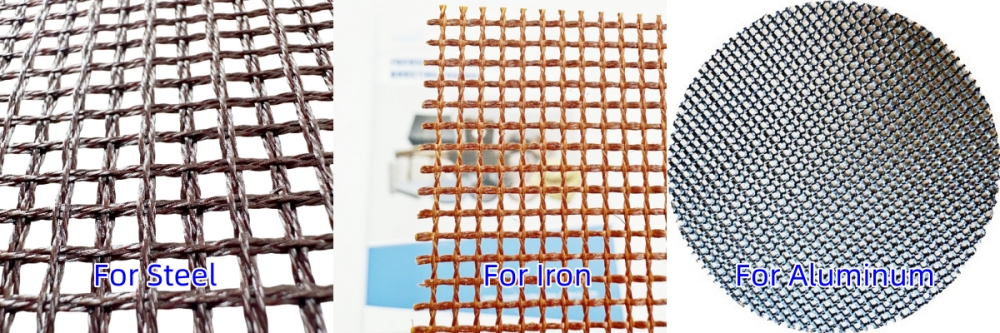

It can be divided into liquid steel, liquid iron, liquid aluminum applications according to the different scope of use.

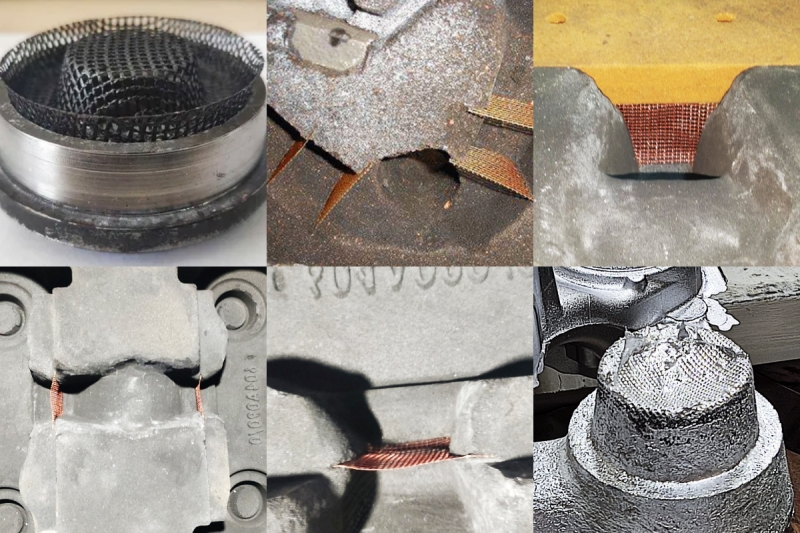

1. First of all, Choose the placement position of fiberglass filter mesh:

There are three main placement positions,

One is placed at the top of the sprue under the sprue cup,

Two is placed at the lap of the cross sprue,

Three is placed at the corner contact between the cross sprue and the inner sprue.

2. Place filter mesh on the parting surface:

There are two placing ways,

One is horizontal placement, also can be said to be parallel placement, the filter is placed horizontally under the crossmouth cup or parting surface, the casting height should not exceed 20 cm, the metal liquid is washed at the intersection cup wall, not directly to the filter mesh;

Two is vertical placement.

3. The filter mesh is placed on the top, and the bending surface should be kept upward and flattened from the center to the four sides. At the same time, the filter mesh can not have wrinkles.

1. Adequate mechanical strength

If the mechanical strength of filter mesh is not enough, it is very easy to break and drop chips. It is unfavorable to storage and transportation, and on the other hand, once the chips fall into the aluminum liquid in the filtration, it will cause the bad quality of the ingot.

2. Resistance to hot aluminum liquid scour

When the aluminum is filtering, the high-temperature aluminum liquid suddenly contacts the surface of the filter mesh, in a very short time, the filter mesh is heated too much, and the liquid heat makes the filter mesh quickly rise temperature close to the metal liquid. The filter mesh is instantly expanded by heat, which requires no cracking after heating, and because the liquid aluminum is constantly carried out, the fiberglass filter mesh can not be damaged by scour and soften and deform by high temperature.

3. Stable chemical properties

Aluminium is easy to react with some substances especially in the high temperature liquid, so it is required that fiberglass filter mesh must be with stable chemical properties, which can not react with aluminium. Then ensure the casting quality.

The liquid aluminum in contact with the air is easy to be oxidized, resulting in impurities such as oxide skin, and the quality requirements of aluminum castings are also very high, it can be a good solution to solve such problems that use fiberglass filter mesh.

Fiberglass filter mesh is suitable for all kinds of aluminum alloy casting, such as sand casting, mold, shell mold, drawing die, investment casting and other fields.

It can effectively remove impurities, eliminate bubbles, thereby improving casting quality and reducing production costs.

At the same time, fiberglass filter mesh does not pollute the aluminum liquid, does not affect the chemical properties of the metal, will not pollute the aluminum liquid, and reduce the cost.

Fiberglass Filter Mesh Are Exported To Our Abroad Client

Jan. 14, 2026

TF COMBO BAG to filter aluminum ingot and billet

Jan. 13, 2026

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation