Zirconia molten metal foam filter uses high-purity zirconia as the basic raw material, which can withstand high temperatures above 1700°C.

It has very high strength and excellent resistance to high thermal shock, and stable in texture, not easy to be damaged and slag.

The best choice for filtering of determined for all types of steel such as non-alloy, low alloy, stainless steel and high alloy.

Filters are recommended especially for high quality grades of alloys.

Parameter

Zirconia ceramic filter is made of high-purity, high-quality zirconia, with a unique formula and advanced environmental protection technology. Zirconia ceramic foam filters are used to melt all types of steel such as non-alloy, low alloy, stainless steel and high alloy. Filters are especially recommended for alloys of high-quality grades. They have good resistance to attack and corrosion of liquid steel, can effectively remove inclusions in liquid metal, reduce trapped gas in liquid metal, and provide laminar flow so that the filtered metal is significantly clean. Cleaner metals lead to higher-quality castings, less scrap and fewer inclusion defects. Zirconia ceramic foam filters are the best choice for filtering of determined for filtering of steel and steel alloys up to the temperature of 1700℃.

Currently, there is a large-scale ceramic production line in our factory, we can produce many types of Zirconia ceramic foam filters according to the client's own requirements. Our Zirconia ceramic foam filters have passed the RoHS And Reach tests and are certified.

Application: For the filtration of molten steel and alloy, large-scale iron casting.

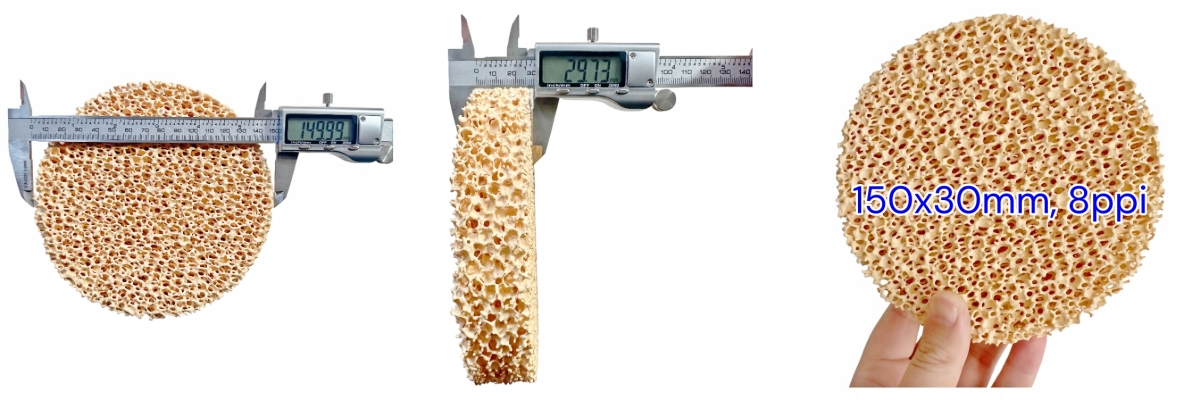

The filters are available in different sizes, making them suitable for various casting processes. With Cangchen ceramic filters, customers can achieve cost-effective solutions to their casting needs, resulting in higher productivity and profitability. Contact us today for more information about Zirconia Ceramic Foam Filters or any of our other innovative products.

| Type | Zirconia ceramic foam filter for steel and high alloy |

| Color | Yellow |

| Brand | Cangchen |

| ZrO2(%) | 85-90 |

| Al2O3 (%) | 5-10 |

| SiO2(%) | ≤4 |

| MgO(%) | 4-5 |

| Porosity | 80-90% |

| Bulk Density | 0.8-1.5g/cm3 |

| Compressive strength | ≥1.5Mpa(Room temperature) |

| PPI | 10-40PPI(PPI=pores per inch) |

| Work Temperature | ≤1700℃ |

| Thermal shock resistance (Times/1100°C) | 6 |

| Certificate | ISO9001:2015 |

| REACH & RoHS |

| Dimensions (mm) | Zirconia Ceramic Foam Filter | |

| Pouring Rate(kg) | Filtration Capacity(kg) | |

| 50×50×22 | 3~5 | 30 |

| 50×75×22 | 4~6 | 40 |

| 75×75×22 | 7~12 | 60 |

| 75×100×22 | 8~15 | 80 |

| 100×100×22 | 14~20 | 100 |

| Dia 50×22 | 2~6 | 18 |

| Dia 80×22 | 6~10 | 50 |

| Dia 90×22 | 8~16 | 70 |

● Cangchen offers Zirconia Ceramic Foam Filters in all standard dimensions and different thicknesses.

● Custom-made cut-to-size filters are also possible. Get an online quote now.

1. Adjust the metal flow rate through rectification to reduce secondary inclusion and pores.

2. Reduce casting inclusion and reduce casting waste and welding repair rate.

3. Improve the surface quality and mechanical properties of the castings.

● Reduction in inclusion levels

● Good filtration capacity

● Ideal for the filtration of high-alloyed steel

● High efficiency

● Filters can be preheated for investment casting application

Molten metal is poured through the porous ceramic structure of the filter. The filter captures and retains impurities and solid particles while allowing the clean metal to pass through. This results in cleaner, higher-quality castings.

Zirconia Ceramic Foam Filters are suitable for filtering a wide range of metals and alloys, including aluminum, steel, copper, and various other non-ferrous metals.

While Zirconia Ceramic Foam Filters can withstand multiple uses, their effectiveness may diminish over time due to clogging from accumulated impurities. They can often be cleaned and reused several times before replacement is necessary.

For each production process, we have a complete QC system for the chemical composition and Physical properties. After production, all the goods will be tested, and the quality certificate will be shipped along with the goods.

We accept OEM service.

Yes, for sure, you are welcome to visit our company.

Yes, we would like to send the samples for you to check the quality.

Our filters are designed to meet the demanding requirements of alloy casting, providing efficient and reliable filtration to ensure the production of high-quality alloy products, Constructed from high-purity zirconia ceramic materials, our filters boast excellent thermal and chemical stability, making them ideal for use in extreme casting conditions. The open-cell structure and high porosity of the foam filter allow for the effective removal of impurities and inclusion from molten metal, resulting in a cleaner and more refined casting, Our Zirconia Ceramic Foam Filters are available in various shapes and sizes to suit different alloy casting applications. Whether it's for aluminum, copper, or other alloy metals, our filters can optimize the casting process and enhance the quality of the final products, At Cangchen, we are committed to providing top-notch ceramic filtration solutions to meet the diverse needs of alloy casting industries.

Please feel free to contact us if you have any questions if you are interested.

Application:

Zirconia ceramic foam filter is used for molten all types of steel like unalloyed, low alloyed, stainless, and high-alloyed as well as Nickel and Cobalt based super-alloys casting.

Look forward to hearing from you:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation