Alumina Ceramic Foam Filter (CFF) blocks are advanced filtration materials widely used in the casting and foundry industries to remove non-metallic inclusions and impurities from molten aluminum and aluminum alloy melts. Made primarily from aluminum oxide (Al₂O₃), these filters feature a three-dimensional porous structure that provides excellent thermal stability, mechanical strength, and chemical resistance.

Widely used in casting processing, water treatment, chemical industry, environmental protection and other industries. It is the ideal liquid aluminum filter; Catalyst support, and good sound insulation, thermal insulation material. Product shapes, sizes, and voids PPI can be designed and manufactured on request.

The alumina ceramic foam products are mainly used in the purification process production of non-ferrous alloys such as aluminum and aluminum alloys, and can also be used as gas-solid, liquid-solid separation medium, catalyst substrate, ceramic burner, sound absorption, environmental protection, and other fields.

Parameter

There are many reasons for aluminum pollution.

On the one hand, in the smelting process, aluminum is exposed to the furnace atmosphere in a molten or semi-molten state, easy to oxidize, easy to react with water vapor and absorb hydrogen, easy to form various forms of non-metallic slag (such as furnace lining debris, chloride, carbide in flux, etc.) and coarse metal intercompound particles and so on.

On the other hand, non-aluminum impurities are carried in during the process circulation by some of waste materials maked up the charging material.

Because the waste is coming from the process waste and scrap during each process in factory and the waste outside the factory, so, the composition is complex due to different way as well as the quality is poor. These impurities often make the billet produce bubbles and inclusions, which seriously affect the purity of the metal melt, thus further affect the processing properties, mechanical properties, corrosion resistance and the appearance quality of the product.

Alumina foam ceramic filter blocks can effectively remove all kinds of inclusions with fineness up to micron level in aluminum liquid, make aluminum liquid into a steady laminar flow, which is conducive to filling.

It has a unique mullite-corundum structure, good mechanical strength and chemical stability, excellent resistance to aluminum liquid erosion performance.

It can obtain stable filtration effect by strict control of hole size and through hole rate.

The ceramic foam filter block is surrounded by a sealing ceramic fiber liner, which facilitates the seal of the filter plate in the filter box to ensure that there is no metal liquid sideflow.

Mainly used for the filtration of molten aluminium and alloys in foundries and cast houses. With the excellent resistance to attack and corrosion from molten aluminum, the filter can effectively remove inclusions, reduce trapped gas and provide laminar flow,and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to the bottom-line profit.

Alumina Ceramic Foam Filter Blocks are indispensable in modern aluminum casting processes, ensuring superior metal purity and performance. With high thermal stability, strong mechanical integrity, and excellent filtration efficiency, they are a reliable solution for improving product quality in high-demand industries.

| Type | Alumina ceramic foam filter for aluminum and alloy |

| Main material | Al2O3, SIO2 |

| Work Temperature | ≤1200℃ |

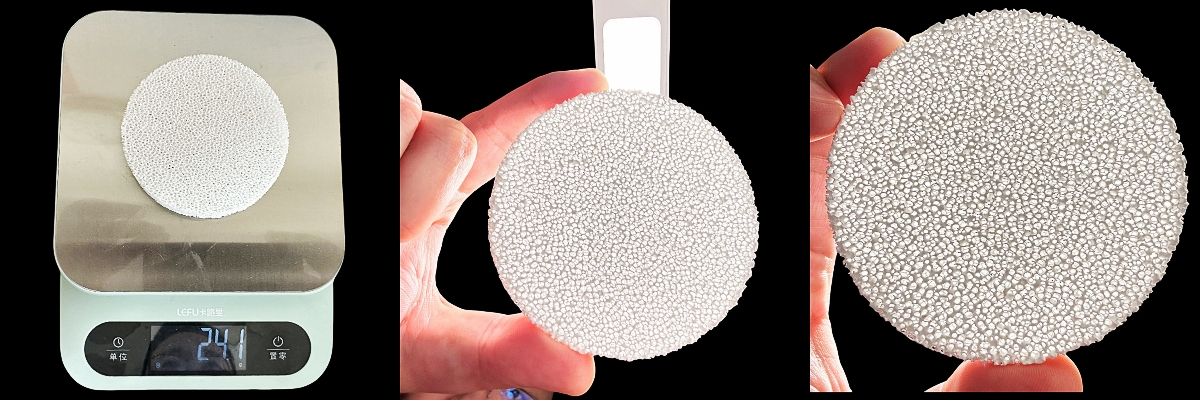

| Color | White |

| PPI | 10/20/30/40PPI(PPI=pores per inch) |

| Porosity | 80-90% |

| Compressive strength | ≥0.8Mpa(Room temperature) |

| Bulk Density | 0.4-0.5g/cm3 |

| Certificate | ISO9001:2015 |

| REACH & RoHS |

High Filtration Efficiency: The open-cell foam structure traps oxides, slag, and other impurities, improving metal purity.

Excellent Thermal Shock Resistance: Can withstand rapid temperature changes in molten metal streams.

Mechanical Strength: Maintains structural integrity even under high metal flow rates.

Chemical Stability: Resistant to corrosion and erosion by molten aluminum and its alloys.

High Porosity: Typically 10–60 pores per inch (PPI), offering customizable flow and filtration performance.

Alumina ceramic foam filter blocks are mainly used in the purification process production of non-ferrous alloys such as aluminum and aluminum alloys, and can also be used as gas-solid, liquid-solid separation medium, catalyst substrate, ceramic burner, sound absorption, environmental protection, and other fields.

● Purify metal molten liquid

● Simplify pouring system

● Improve the casting metallographic structure

● Reduce inclusions in castings

● Reduce the reoxidation defects of castings internal

● Reduce surface defects of castings after machining

● Improve casting qualification rate

Application:

Filtration of molten aluminium

Aluminum Alloys

Molten Aluminium and Alloys in Foundries and Cast Houses

Look forward to hearing from you:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation