Aluminium Ceramic Foam Filter Plate is suitable for the filtration and purification of aluminum and alloy solutions with 1000 ℃.

Alumina foam ceramic filter plate is very important to the quality of aluminum melt, which affects the subsequent processing performance and the quality of final products to a great extent. Therefore, all countries in the world attach great importance to the purification of aluminum melt.

Filters are also widely used in ordinary sand casting, such as wet mold casting, and fixed mold casting, such as automotive aluminum parts casting.

Effectively removes the solid inclusions in the Peirong metal, so the aluminum alloy can be smoothly forged, aluminum foil manufacturing extrusion processing and other processes to obtain high-quality products.

Parameter

CangChen Alumina foam ceramics is a kind of foam material made from high-purity alumina. The foam ceramics have the characteristics of uniform porosity, high-temperature resistance, heat shock resistance, wear resistance and chemical stability. Aluminium Ceramic Filter Plates are widely used in casting processing, water treatment, chemical industry, environmental protection and other industries. Is the ideal liquid aluminum filter; catalytic support, and good sound insulation, and thermal insulation material. Product shapes, sizes, and voids of PPI can be designed and manufactured on request.

Regular Size:

| Dimension | Tolerance | Thickness | Rake Angle | Tortuosity | Diagonal Line |

| 12"/305mm | ±3mm | 50mm±1mm | 17.5°+1° | Max.4mm | <1% of side length |

| 15"/381mm | ±3mm | 50mm±1mm | 17.5°+1° | Max.4mm | <1% of side length |

| 17"/432mm | ±3mm | 50mm±1mm | 17.5°+1° | Max.4mm | <1% of side length |

| 20"/508mm | ±4mm | 50mm±1mm | 17.5°+1° | Max.4mm | <1% of side length |

| 23"/584mm | ±4mm | 50mm±1mm | 17.5°+1° | Max.4mm | <1% of side length |

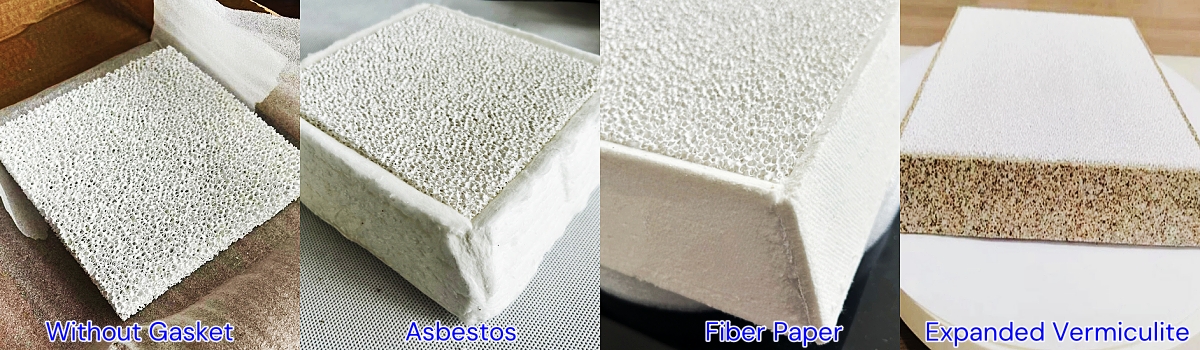

*Remarks: There are no cracks and obvious defects on the surface, no slag, and sealing cotton around it, the thickness is 7mm-10mm.

Physical performance indicators:

| Color | White |

| Gaskets | Asbestos---Normal |

| Fiber Paper---Medium | |

| Expanded Vermiculite---Superior | |

| PPI | 10/20/30/40/50/60(Customized) |

| AL2O3 | 80%-90% |

| SiO2 | <10% |

| MgO | >10% |

| Porosity | ≥85% |

| Proportion | 0.3g/cm³-0.45g/cm³ |

| Refractory temperature | ≥1500℃ |

| Bending strength | >0.5Mpa |

| Thermal shock resistance | 750℃/5times |

| Solubility | Under the temperature of metal aluminum and aluminum alloy solution, the filter equipment will not chemically react with the solution and dissolve. |

| Certificate | ISO9001:2015 |

| REACH & RoHS & MSDS |

CangChen is a leading manufacturer and factory specializing in the production of Aluminium Ceramic Filter Plates. With years of experience and expertise in the industry, we have established ourselves as a trusted supplier of high-quality filter plates that meet the diverse needs of our clients.

If you are looking for a reliable and reputable manufacturer and factory of Aluminium Ceramic Filter Plates, look no further than CangChen. Contact us today for more details about our products, specifications, and parameters. Our team is ready to assist you with any questions or concerns you may have and help you find the perfect solution for your filtration needs.

● Alumina foam ceramic filter plate can effectively remove all kinds of inclusions with fineness up to micron level in aluminum liquid, making aluminum liquid into a steady laminar flow, which is conducive to filling.

● It has a unique mullite-corundum structure, good mechanical strength and chemical stability, and excellent resistance to aluminum liquid erosion performance.

● It can obtain a stable filtration effect by strict control of hole size and through hole rate.

● The ceramic foam filter plate is surrounded by a sealing ceramic fiber liner, which facilitates the seal of the filter plate in the filter box to ensure that there is no metal liquid side.

● A selection range of 10ppi coarse porosity to 40ppi very fine porosity.

1. Copper alloy casting filtration,

In the casting process, Non-ferrous metal melt (brass, bronze, zinc, tin) also will generate oxidation, non-metallic debris and a large number of waste products. It can greatly reduce the rate of scrap if use foam ceramic filter plate. 1.0 ~ 1.2mm mesh with cordierite material is the best choice for the filtration of copper alloy.

2. Catalyst carrier for vehicle exhaust purification processor,

The foam ceramics have been widely used as the carrier of automobile exhaust catalytic purifiers because of their large surface area, good thermal stability, wear resistance, resistance to poisoning and low density.

The foam ceramic automobile exhaust catalytic purifier installed in the exhaust pipe of the gasoline car can make the harmful gas CO, HC, and NOx discharged from the gasoline car into CO2, H2O, and N2, and the conversion rate can reach more than 90%; Used in diesel vehicles, carbon particle purification rate in more than 50%. When the foam ceramic filter element is full of carbon particles, the catalytic oxidation method or electronic combustion method can be used to regenerate, and constantly eliminate the deposited carbon particles, to achieve the purpose of long-term use.

3. In special fields,

The other applications under high-temperature conditions, foam ceramics have excellent thermal radiation characteristics, which are used to enhance heat transfer and combustion technology in porous media with remarkable results. Foam ceramic can also be made into a photocatalyst carrier, coated with nano titanium dioxide on the foam ceramic carrier, excited by ultraviolet light, has strong photocatalytic oxidation and degradation characteristics, can catalyze the degradation of organic matter and microorganisms, to purify the air. Foam ceramics can also be made into chemical tower packing, gas distribution materials, and gas stove energy-saving combustion plates.

( Purified Air Function of Alumina Ceramic Foam Filter Plate As A Carrier )

Application:

Filtration Of Molten Aluminium

Molten Aluminium Alloy

Ductile and steel alloy

Ferrous metals including grey

Copper-based alloys

Look forward to hearing from you:

Contact Us

+86 158 3011 4065

Guoruiyuan Building, ShengLi North Street, Chang'An District, Shijiazhuang City, Hebei Province, China.

Navigation

Navigation